I-Compex luphawu lwase-Itali lweereli ezikhokelayo ezifanelekileyo kwizicelo ezifana needrowa zasekhitshini, iikhabhathi, kunye neendlela zomnyango/iifestile. Kwiminyaka yakutshanje, iYurophu neMelika zingenise inani elikhulu leereli ezikhokelayo, kunye nemfuno enkulu yeendidi zentsimbi engagqwaliyo zorhwebo. Ukuveliswa kwazo kufuna ubuchule obuphezulu bobuchwephesha, njengoko kufuneka zimelane neemeko ezahlukeneyo ngelixa zibonelela ngokumelana nokugqwala kunye nomthamo ophezulu wokuthwala umthwalo. Ubukhulu kufuneka bube ngqo kwi-millimeter. Ngokwemvelo, ukuqonda ukufakwa kwereli ekhokelayo kubalulekile.

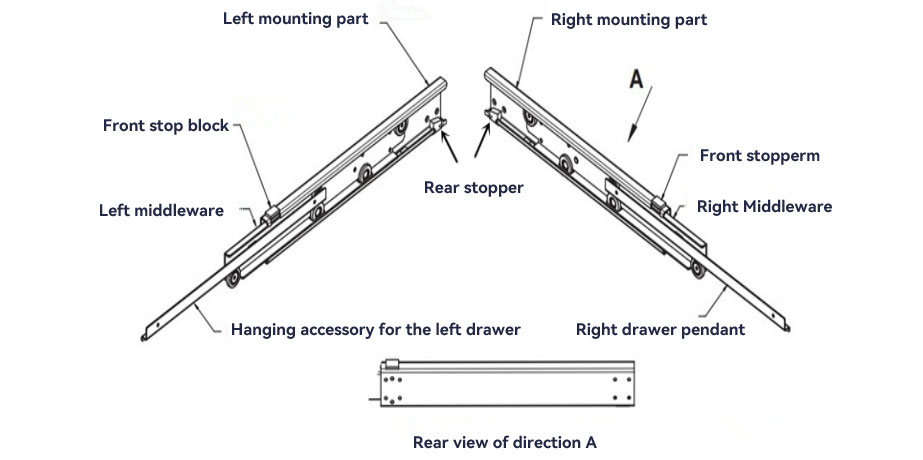

I. Masiqale sihlolisise umzobo wolwakhiwo lwereyile yesikhokelo, njengoko kubonisiwe ngezantsi:

Ireyile ekhokelayo inamacandelo amane amakhulu: izibiyeli zokufakela, izihlanganisi eziphakathi, izixhobo zokufakela, izitophu zangaphambili, kunye nezitophu zangasemva.

Ubude bemveliso:300mm~~750mm

Ubude obupheleleyo (ubude bemveliso + ubude bokusebenza):590mm ukuya kwi-1490mm

Iindlela zokufaka:Ukufakelwa kohlobo lwehaki + Ukufakelwa kohlobo lweskrubu

II. Umzobo woFakelo lweSitimela seDrowa

Ukufakwa kweSitimela seSikhokelo seDrowa

Okokuqala, khetha iireli zesikhokelo ezifanelekileyo ngokusekelwe kwimizobo yoyilo lwemveliso ukuze ukhethe uhlobo lwereli olufanelekileyo

1. Faka izibiyeli zedrowa zasekhohlo nasekunene:

a. Ngaphambi kokuba ugobe idrowa, bhoboza imingxunya yokubeka indawo (ehambelana nemingxunya emibini yokufumana indawo kwibrakethi yedrowa) ukuqinisekisa ukuba umgca othe tye wemingxunya yokufumana indawo kumacala omabini uhlala uhambelana emva kokugoba.

b. Emva kokwenza idrowa, linganisa ubude becala ngalinye ngeteyipu yokulinganisa ukujonga ukuba kukho ukunyamezelana kokugoba na. Ukuba ukunyamezelana kokugoba kugqithisile, idrowa akufuneki isetyenziswe.

c. Zikhusele iibrakethi zedrowa usebenzisa i-spot welding okanye i-full welding. Ukulungiswa kwe-adhesive yexeshana kungasetyenziswa ekuqaleni. Nje ukuba ukudibana kakuhle phakathi kwe-bracket kunye ne-guide rail kuqinisekiswe, qhubeka ne-permanent welding.

2. Xa ufaka iikholamu zenkxaso zangaphambili nangasemva, ikholamu engaphambili kufuneka ilungiswe kuqala, ilandelwe kukulungiswa kwendawo yekholamu engasemva.

2. Indlela:

Misela umgama osecaleni phakathi kweekholamu zenkxaso zangaphambili nangasemva ngokusekelwe kubukhulu bedrowa.

Misela umgama omde phakathi kweentsika zokuxhasa zangaphambili nangasemva ngokusekelwe kubude bendibano ephambili yesitimela.

Misela umgama othe tyaba weposti yokuxhasa engaphambili kwaye uyiqinise ngokuqinileyo ngezikrufu. Umgama othe tyaba ngqo uxhomekeke kubukhulu obuthe tyaba bedrowa, ubukhulu bebracket yokufaka ireyile yesikhokelo, ibracket ephakathi, kunye nebracket yokuxhoma idrowa. Okulandelayo, yenza umqadi onqamlezileyo olingana nobude obuthe tyaba bekholamu yokuxhasa engaphambili. Oku kwenza kube lula ukumisela umgama othe tyaba wekholamu yokuxhasa engasemva ngelixa ukhusela ikholamu yokuxhasa engasemva ukuthintela ukuguquka okubangelwa kukwandiswa kwefoam yekhabhinethi.

b. Linganisa umgama phakathi kweendawo zangaphambili nezingasemva ze-spot-weld okanye iindawo ze-hook kwiireyile zesikhokelo. Sebenzisa umqadi onqamlezileyo ozinzileyo ukuze uqinise indawo yokufaka ikholamu yokuxhasa engasemva;

c. Bopha umqadi onqamlezileyo kwikholamu yokuxhasa engasemva kunye nekholamu yokuxhasa engasemva kwikhabhinethi usebenzisa izikrufu okanye ezinye iindlela. Oku kugqiba ukufakwa kweekholamu zokuxhasa zangaphambili nangasemva.

3. Amanqaku okufaka:

a. Iireyile zesikhokelo zohlobo lwehoko: Izixhasi zinemingxuma yeehoko. Ubukhulu bepleyiti yentsimbi exhasayo yi-1mm; ngokubanzi, ubukhulu bepleyiti yentsimbi akufuneki budlule kwi-2mm njengoko ububanzi bemingxuma yeehoko bumalunga ne-2mm.

b. Iireyile zesikhokelo ezifana nezikrufu: Musa ukufuna imingxunya yeehoki kwaye musa ukufaka mfuneko ingqongqo yobukhulu kwiipleyiti zentsimbi.

4. Ukufakela iinxalenye zeSitimela esiPhambili seSikhokelo

Faka idrowa, efakwe ii-hangers zayo zedrowa zasekhohlo nasekunene, kwindawo yokutyibiliza ukuze ugqibezele ukuyifaka.

a. Iireli zesikhokelo zohlobo lwehoko: Hlikihla indibano yereli yesikhokelo ephambili kwiinsika zenkxaso zangaphambili nangasemva. Ukuba iihoko zibonakala kunzima ukuzifaka okanye zisenokuphuma lula, lungisa iindawo zeentsika zenkxaso ngokufanelekileyo.

b. Iireli zesikhokelo zohlobo lweskrubu: Qinisekisa izinto eziphambili zereli yesikhokelo kwiikholamu zenkxaso zangaphambili nangasemva usebenzisa i-spot welding, i-arc welding, okanye ii-screws.

Umzobo wokufakelwa kweereyile zesikhokelo zeefriji zorhwebo:

Xa ugqibile ukufaka izilayidi, ukusilela ukujonga iindlela ezifanelekileyo kunye neenkcukacha kudla ngokukhokelela kwimiba elandelayo:

I. Izizathu zokuxinana kweedrowa kunye nengxolo egqithisileyo:

1. Ufakelo lweslayidi olungahambelaniyo. Isisombululo: Sebenzisa i-spirit level ukuqinisekisa ulungelelwaniso oluhambelanayo lweslayidi, ukusombulula ukungangqinelani kwesithuba esithe tye kuzo zombini iislayidi kunye neebrakethi zokufakela.

2. Umgama ongaguqukiyo phakathi kwabagijimi kunye nezibiyeli.

Iindlela zingabandakanya:

a. Iitshaneli zepleyiti yentsimbi enobubanzi obuzinzileyo b. Isinyithi se-engile yenkxaso yangasemva esimile okwe-L + umqadi onqamlezileyo wenkxaso yangasemva enobubanzi obuzinzileyo

c. Izithuba zokulungisa isithuba esithe tyaba kwikholamu yokuxhasa

Izinto ezibalulekileyo ekufuneka uziqwalasele:

a. Ukunyamezelana kokwenziwa kweedrowa zokulawula, ukuqinisekisa ukuba isithuba esithe tye ukusuka ngaphambili ukuya ngasemva asidluli kwi-1mm

b. Kuphephe ukuguqulwa kwe-welding yebracket

c. Qinisekisa ukuba iindawo zokuwelda zanele ukuwelda ngokupheleleyo okanye okubonakalayo

II. Ukuqina okungazinzanga, okunokutsalwa lula – qinisekisa ukuba ibhloko yokumisa ngaphambili ayifakwanga na.

Xa ukhetha abagijimi beedrowa, eyona nto iphambili ekufuneka iqwalaselwe ngumgangatho wentsimbi. Kubalulekile ukuqaphela ukuba amandla okuthwala umthwalo wedrowa aphenjelelwa kakhulu ngumgangatho wentsimbi yokubaleka. Iinkcukacha ezahlukeneyo zeedrowa zifuna ubukhulu bentsimbi obahlukeneyo. Abagijimi beCOMPEX basebenzisa intsimbi engagqwaliyo engama-304 engeniswe kwamanye amazwe, enika ukuchaneka okuphezulu kunye nobomi benkonzo obude. Zonke iipulleys kwiindawo zokuqhaqha zenziwe ngezinto ze-nylon 6.6. Intuthuzelo yokusebenza kwepulley inxulumene kakhulu nokwakheka kwazo. Iipulleys ezifumaneka rhoqo zisebenzisa iibhola zentsimbi okanye i-nylon, kunye neepulleys ze-nylon ezimele ukhetho oluphezulu, ezisebenza buthule ngexesha lokusetyenziswa. Ngaphezu koko, umgangatho weepulleys unokuvavanywa ngokutyibiliza idrowa ngesandla ukujonga naluphi na uxhathiso, ingxolo, okanye ukurhawuzelela. Ulwazi olungentla lubonelela ngentshayelelo yokufakelwa kweereyile zesikhokelo zeCOMPEX. Siyathemba ukuba olu mxholo luya kuba luncedo xa lufuneka.

Ixesha lokuposa: Okthobha-16-2025 Imbono: