Cake cabinets come in different standard models and specifications. For a 2 – tier shelf cake display cabinet, the shelves are designed with adjustable height, fixed by snap – on fasteners, and it also needs to have a refrigeration function. A high – performance compressor is essential for this, and the factory needs a certain amount of time and a specific process to produce it.

Nenwell stated that from February to March 2025, the factory’s manufacturing output declined. Sometimes, not even one unit was produced in a day, while usually around 20 units were produced daily. Due to tariff issues, the order volume decreased to 10%, and this was for a medium – to – large – sized factory.

When a factory produces a commercial cake cabinet, it needs to use sufficient materials and ensure precise dimensions. Otherwise, it will be difficult to pass the subsequent qualification certifications. Common certificates include CE, CCC\UL, VDE, etc. For example, testing whether the nickel content in stainless steel 304 meets the standard and whether the power supply specifications are qualified. Each component is produced by the factory.

In the production workshop, you will see various production equipment, mostly in the assembly – line series. Common ones include bending machines, injection – molding machines, cutting machines, laser welding machines, etc. Without sufficient equipment, it is difficult to complete the manufacturing of an arc – shaped cake cabinet.

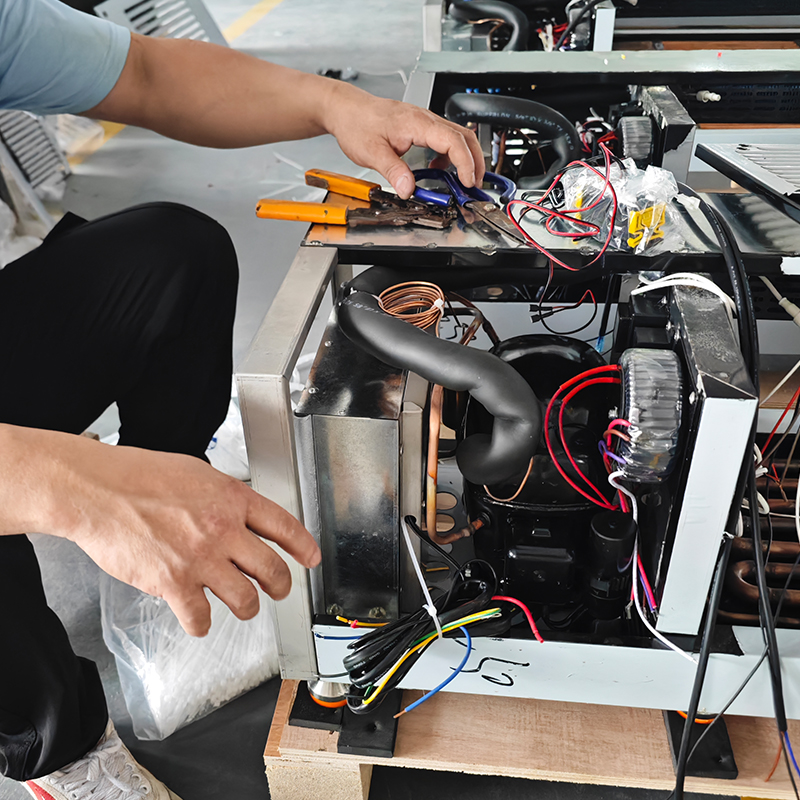

Of course, the factory does not produce all components. Some important parts need to be purchased separately, such as compressors, condensers, temperature controllers, etc. The overall external unit of the cabinet must be customized according to the size specifications by the factory. Then, workers assemble it with the help of various equipment. Assembly is a major task. Due to the complex structure of the equipment, manual adjustment of some details is required, such as grinding the edges after welding. The glass panel is glued to the cabinet body, and subsequent glue – removal work is needed.

After the assembly of the cake display cabinet is completed, it needs to go through various testing processes to ensure that its performance, safety, and practicality meet the requirements. The main types are as follows:

1.Function Testing

Check whether the core functions are normal, such as whether the refrigeration system can reach the set temperature (usually cakes need to be stored at 2 – 10℃), whether the temperature control is accurate, whether the lighting system (such as LED lights) is on and the illumination is uniform, whether the glass door opens and closes smoothly, and whether the sealing is good (to prevent cold air leakage).

2.Safety Testing

Verify electrical safety, such as whether the insulation of the power cord meets the standard and whether the grounding is reliable to avoid the risk of electric shock. Check the structural stability of the cabinet, such as whether the load – bearing capacity of the shelves meets the design requirements (to prevent cakes from toppling when placed), whether the edges are smooth without burrs (to avoid scratches), and whether the tempered glass meets the safety standards.

3.Operational Stability Testing

Run continuously for a long time (usually 24 – 48 hours), observe whether the temperature remains stable, whether there is abnormal noise, and whether components such as the compressor overheat, ensuring that the equipment is less likely to malfunction during long – term use.

4.Appearance and Detail Inspection

Check whether there are scratches or paint peeling on the surface of the cabinet, whether the glass is intact without cracks, whether each component is firmly installed (such as no loose screws), and whether the overall aesthetics meet the display requirements.

Note that these tests can effectively avoid potential safety hazards of the equipment and ensure its normal use in the future. For food – grade commercial cake cabinets, strict and standardized testing must be carried out, with attention to details and manufacturing processes.

Post time: Jul-30-2025 Views: