A deep – freeze freezer refers to a freezer with a temperature lower than – 18°C, and it can even reach -40°C~- 80°C. The ordinary ones can be used to freeze meat, while those with lower temperatures are used in laboratory, vaccine and other system equipment.

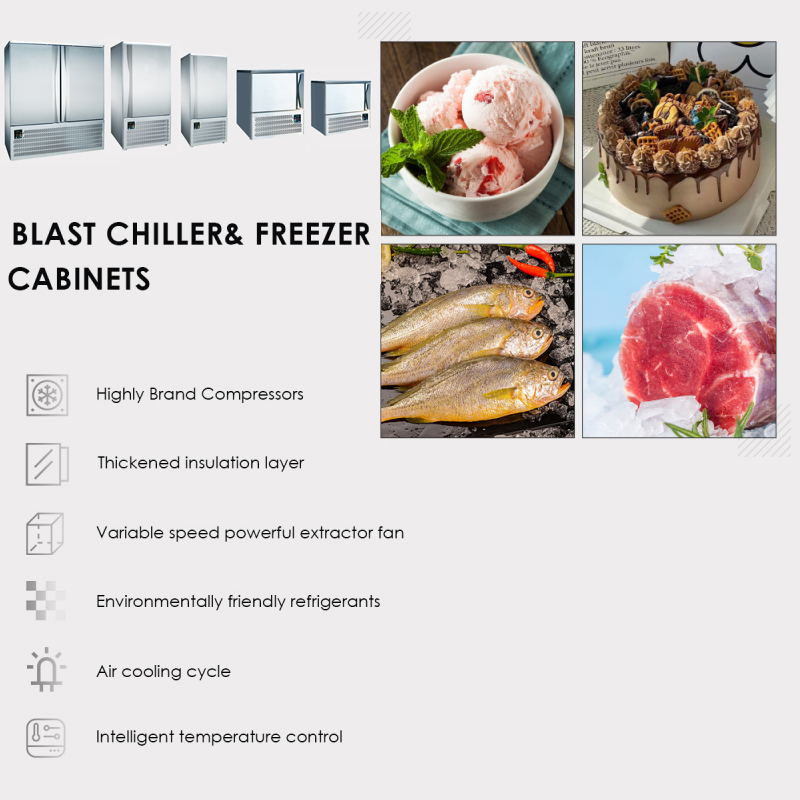

The ordinary – type freezer is used for storing seafood food, with a temperature range of – 18°C to – 25°C. It has a high refrigeration efficiency and adopts a high – performance compressor, which is very stable for long – term use. At the same time, in many aspects, for example, its functions are relatively single.

The regular functions include an air – cooling system, digital temperature control display, and convenient mobility. This is completely sufficient for just freezing food and can meet the needs of 80% of the shopping malls in the market.

In terms of materials, if it is an imported brand supplier, most of them use high – quality stainless – steel materials. Components such as compressors, evaporators, and condensers are all qualified and have comprehensive qualification certificates and service guarantees.

The temperature of a laboratory deep – freeze freezer can reach – 40°C to – 80°C. It uses a customized compressor, has a stable refrigeration temperature, has all the functions of an ordinary freezer, and is equipped with a professional intelligent temperature control monitoring system and a safety warning function. It not only has accurate temperature control and an excellent user experience but also has a relatively high price.

In developed countries, tens of millions of dollars are invested in experiments every year. Most of the freezing instruments come from importers. Due to price differences and other factors, but more importantly, from the perspective of funds, in fields such as schools, when the funds are not high, it can be considered to import some inexpensive equipment.

What are the factors to consider when choosing a freezer?

First of all, the price factor should be considered. For any enterprise or group, when importing professional refrigeration equipment, the first thing to check is whether the budget is sufficient. Select the equipment in the market that meets the price conditions according to the budget. If the price of the supplier is higher than that of the general user group, it will be difficult to sell. If the price is too low, it is not conducive to the production and development of the enterprise. Of course, it is very important to understand the market price comparison. There are price differences in different regions such as Europe, America, and South Asia.

Secondly, brand after – sales service is very important. Even the most high – end and high – quality equipment may have service problems, including fault – handling, usage guidelines, etc. Some freezing equipment even needs to be trained before use. If it is not used professionally, it will also cause damage to the equipment. An important part of procurement is to understand the service of the enterprise, its global scale and brand index.

After considering these two important factors, the quality and functions of the freezer need to be focused on. Both consumers and manufacturers should strictly control the quality. Although many brands have comprehensive qualification certificates, it does not mean that the equipment has no problems at all. For example, there may be no problems in the production and packaging process, but problems may occur during transportation. For purchasers, it is very important to do a strict acceptance work.

Of course, the signing of the contract by both parties also needs to be done carefully. After all, it is to safeguard the interests of both parties. Pay attention to every detail, including liability division, detailed customized functions, etc.

The above is the collation of the content about freezers in this issue. It mainly focuses on the importance of customization choices, understanding different types, prices, and suppliers of freezers, and doing a good job in the evaluation process.

Post time: Aug-06-2025 Views: