Polyester film tape is made by coating pressure – sensitive adhesives (such as acrylate adhesives) on a polyester film (PET film) as the base material. It can be used on electronic components of refrigeration equipment, commercial freezers, etc. In 2025, the sales volume of polyester film tape increased with the increase in the number of equipment exported by manufacturers, accounting for 80% of the annual demand.

What are the specific characteristics?

Thanks to its characteristics such as temperature resistance, insulation, and stable adhesion, polyester film tape has multiple application scenarios in the production and use of refrigerators:

(1) Component Fixing

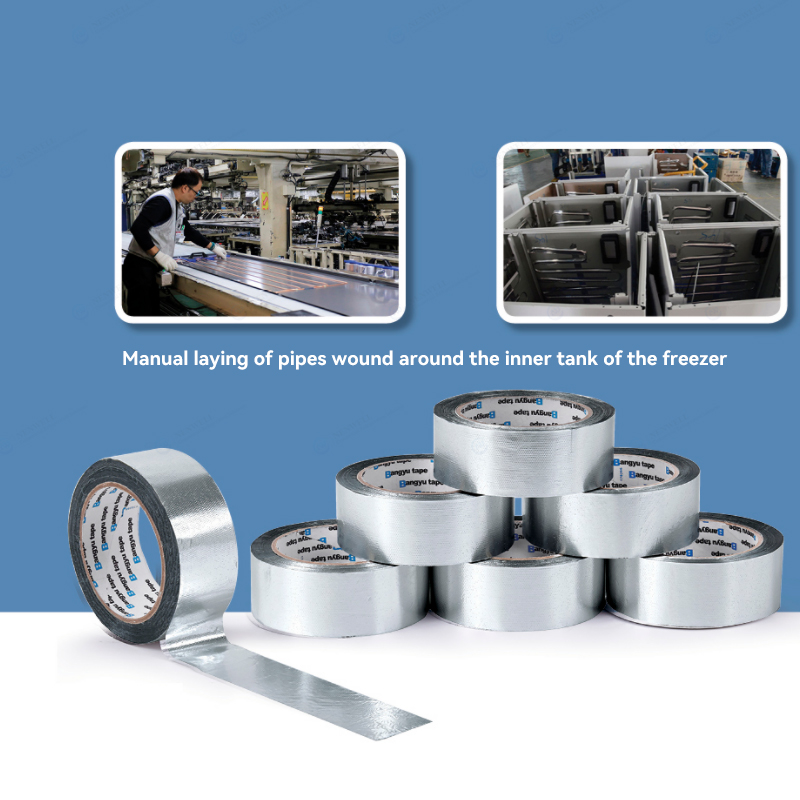

During the refrigerator assembly process, it can be used to fix internal components such as wires and pipes (such as evaporator pipelines) to prevent them from shifting due to vibration during transportation or use.

(2) Insulation Protection

Electrical components (such as refrigerator thermostats and motor wiring connections) require insulation treatment. The insulation performance of polyester film tape can avoid the risks of electric leakage or short – circuit.

(3) Sealing Assistance

At the installation of door seals or the splicing of the refrigerator body, it can assist in enhancing the sealing performance, reducing cold air leakage, and improving the refrigeration efficiency of the refrigerator.

(4) Surface Protection

During the production stage, for easily scratched parts such as the refrigerator shell and glass panel, covering them with polyester film tape can prevent wear during processing or handling, and the tape can be torn off after installation.

Its characteristics of low – temperature resistance (suitable for the low – temperature environment inside the refrigerator) and moisture resistance (to cope with the condensed water vapor inside the refrigerator) enable it to function stably, ensuring the safety and service life of the refrigerator.

What are the common types?

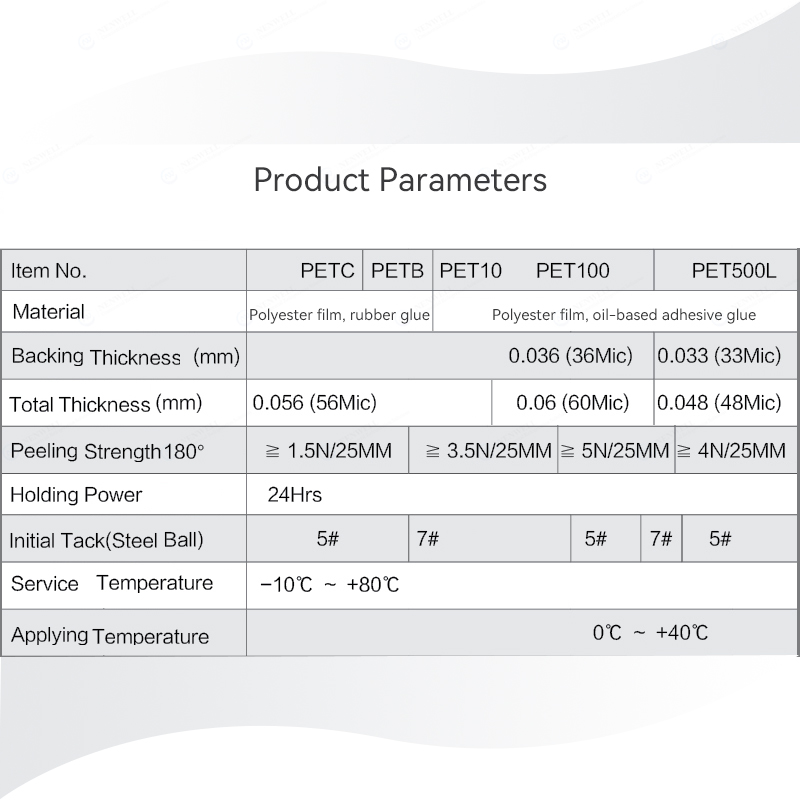

(1) PET10

It uses a polyester film with a base material thickness of 0.036mm, a total thickness of 0.056mm, a peel strength of ≥ 1.5N/25MM, and a service temperature of – 10℃~80℃.

(2) PETB

PETB uses rubber glue, with a peel strength of ≥ 3.5N/25MM. Its service temperature is the same as that of PET10, with slight differences.

(3) PET500L

The base material thickness of PET500L is 0.033mm. Its main components are polyester film and oil – based glue. The peel strength is ≥ 4N/25MM, and the applicable temperature is 0℃~ + 40℃.

What are the application scenarios?

For conventional electronic devices, including small refrigerators, mini beverage cabinets, ice – cream cabinets, cake cabinets, and table – top glass – door air – curtain cabinets, the internal components all use polyester film tape. When using it, it is necessary to operate strictly in accordance with the instructions.

The price of polyester film tape is the lowest. It can be purchased in bulk from the manufacturer. It is necessary to check whether it is qualified and whether it has a production safety license. Of course, choosing a branded one would be better.

Post time: Aug-04-2025 Views: