In the modern baking industry, the lighting system of cake display cases not only affects the visual presentation of products but also directly impacts food preservation quality, energy consumption costs, and overall operational efficiency. With the rapid development of LED technology, more and more businesses are considering upgrading their traditional fluorescent lighting systems to LED lighting. This article analyzes the differences between LED lighting and fluorescent lighting for cake display cases from multiple dimensions including technical characteristics, practicality, economics, and environmental impact, providing scientific selection criteria for operators.

Technical Principles and Basic Characteristics Comparison

LED Lighting Technology Principles

Light Generation Mechanism and Features

LED (Light Emitting Diode) is a solid-state lighting technology based on semiconductor materials. When current passes through an LED chip, electrons and holes combine to release energy, which is directly converted into light energy. This light-emitting method has significant characteristics such as fast response speed, low heat generation, and slow light decay.

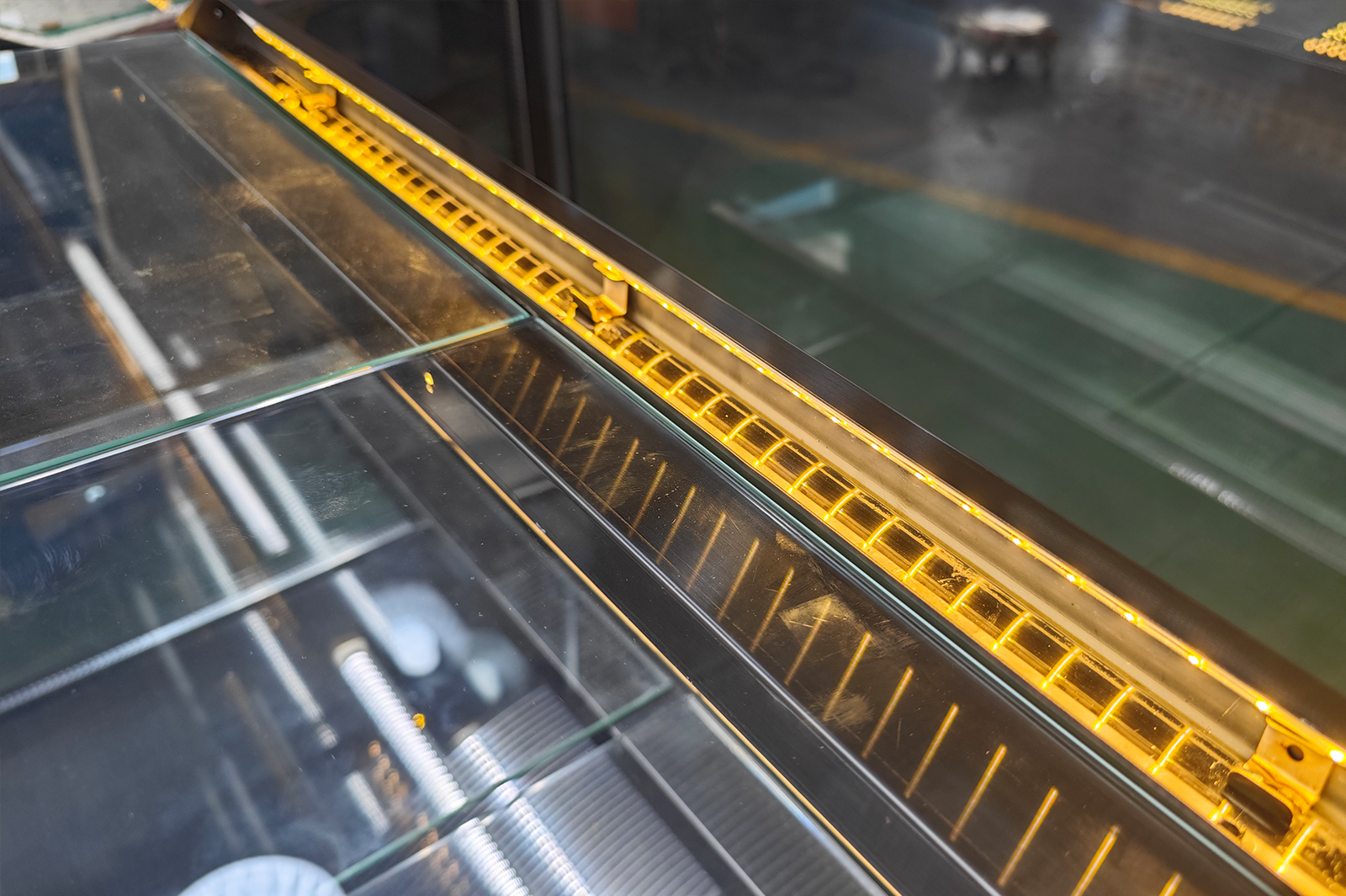

In cake display case applications, LED lighting can provide highly concentrated directional light sources with strong spectral adjustability, enabling precise control of light color temperature and intensity. Modern LED technology can achieve a color rendering index (CRI) of over 90, ensuring true color reproduction of cakes.

Optical Performance

LED lighting demonstrates excellent optical performance with the following key characteristics: luminous efficacy of up to 150-200 lumens/watt, far exceeding traditional lighting; wide color temperature range adjustable from 2700K warm white to 6500K cool white; precisely controllable beam angles typically between 15°-120°; extremely low flicker, effectively protecting visual comfort.

Fluorescent Lighting Technology Principles

Traditional Fluorescent Lighting Mechanism

Fluorescent lamps generate ultraviolet light by exciting mercury vapor through high-voltage electric arcs, and the ultraviolet light then excites phosphor coating on the inner wall of the tube to emit visible light. While this indirect light-emitting method is technically mature, it has inherent limitations in energy conversion efficiency and light quality control.

Traditional T8 and T5 fluorescent tubes are widely used in cake display cases, with luminous efficacy typically between 80-100 lumens/watt. Although costs are relatively low, they gradually show disadvantages in precise lighting control and long-term economic viability.

Technical Limitations of Fluorescent Lamps

Fluorescent lighting has several key technical limitations: longer startup time, typically requiring 1-3 seconds of warm-up; noticeable flicker with working frequency of 50-60Hz that may cause visual fatigue; color rendering limited by phosphor formulation, with CRI typically between 70-85; poor dimming performance, difficult to achieve smooth dimming control; temperature sensitivity with significantly reduced performance in low-temperature environments.

Cake Display Case Lighting Application Performance Comparison

Visual Effects and Product Display

Color Rendering Capability Analysis

In cake display case applications, the color rendering capability of lighting directly affects customer purchasing decisions. High-quality LED lighting can achieve a color rendering index of 95 or higher, truly displaying the color, texture, and appealing appearance of cakes. In comparison, ordinary fluorescent lamps typically have a CRI between 75-85, which may make cake colors appear cold or distorted.

Especially for colorful products like chocolate cakes and fruit cakes, LED lighting can better highlight their layered appearance and appealing visual effects, while fluorescent lamps may make these products appear dull and affect sales performance.

Light Uniformity and Shadow Control

LED lighting systems can achieve highly uniform light distribution through precise optical design, effectively reducing shadows and brightness unevenness within cake display cases. Multi-point arranged LED light sources can create three-dimensional lighting effects, ensuring cakes from every angle receive adequate display lighting.

Due to their linear light-emitting characteristics, fluorescent lamps tend to create striped light and shadow patterns within cake display cases, especially when the cabinet depth is large, leading to lighting blind spots and uneven illumination.

Heat Control and Food Preservation

Heat Generation Comparison Analysis

Baked goods like cakes are very sensitive to temperature, and the heat generation of lighting systems directly affects product preservation and shelf life. LED lighting has an electro-optical conversion efficiency of 40-50%, compared to fluorescent lamps’ 20-25% efficiency, representing a significant advantage. This means LEDs generate far less heat than fluorescent lamps.

| Lighting Type | Electro-Optical Conversion Efficiency | Heat Generation (Relative Value) | Impact on Food Temperature |

|---|---|---|---|

| LED Lighting | 40-50% | Low (Baseline 1) | Minimal Temperature Rise |

| T5 Fluorescent | 20-25% | Medium (2-3x) | Moderate Temperature Rise |

| T8 Fluorescent | 15-20% | High (3-4x) | Significant Temperature Rise |

Preservation Effects and Shelf Life Impact

Low heat generation LED lighting can effectively reduce temperature rise on cake surfaces, preventing cream melting, icing softening, and other quality issues. Research shows that cake display cases using LED lighting maintain temperatures 2-4°C lower than those with fluorescent lighting, which is significant for extending cake shelf life and maintaining optimal quality.

Particularly in summer high-temperature environments, the low heat characteristics of LED lighting become even more apparent, significantly reducing the burden on refrigeration systems and improving overall preservation effectiveness.

Economic Benefits and Operating Cost Analysis

Energy Consumption Comparison

Actual Power Consumption Measurement

Under equivalent lighting effects, LED lighting systems typically consume 50-70% less power than fluorescent lamps. Taking a standard 2-meter cake display case as an example, traditional T8 fluorescent configuration requires 2 × 36W tubes (total 72W), while an equivalent LED lighting system needs only 25-30W to achieve the same or better lighting effects.

Calculating 12 hours of daily operation, LED lighting can save approximately $50-80 in annual electricity costs (based on $0.12 per kWh). For large bakeries with multiple display cases, the annual energy savings will be very substantial.

Refrigeration System Synergy Benefits

The low heat characteristics of LED lighting also reduce the workload of refrigeration systems. When heat from display case lighting decreases, compressor operating time correspondingly shortens, further reducing energy consumption. Comprehensive calculations show that LED lighting in cake display case applications can achieve overall energy savings of 60-80%.

Maintenance Costs and Service Life

Product Lifespan Comparison

LED lighting typically has a rated lifespan of 50,000-100,000 hours, while fluorescent lamps only last 8,000-15,000 hours. Under the intensity of 12 hours daily use in cake display cases, LED lighting can operate for 10-15 years, while fluorescent lamps need replacement every 2-3 years.

Lifespan Cost Calculation Example:

- LED Lighting: Initial investment $150, virtually no replacement needed during 15-year service period

- Fluorescent Lighting: Initial investment $45, but requires 5-7 replacements, total cost approximately $315-420

Maintenance Workload Analysis

Fluorescent lamp systems require regular replacement of tubes, starters, and ballasts, with each maintenance session requiring business suspension and affecting normal operations. LED lighting systems are essentially maintenance-free, and even if individual LED modules fail, they can be quickly replaced through modular design, minimizing impact on business operations.

Environmental Characteristics and Sustainable Development

Environmental Friendliness Comparison

Material Safety Assessment

LED lighting uses solid-state semiconductor technology and contains no harmful heavy metals like mercury or lead. Even if damaged, it will not cause environmental pollution. In contrast, fluorescent lamps contain 2-5mg of mercury, and breakage can cause mercury pollution requiring professional treatment.

In food-grade application environments, the safety advantages of LED lighting are even more prominent, with no risk of harmful substance leakage, ensuring food safety and consumer health.

Carbon Emissions and Lifecycle Impact

LED lighting has a much lower carbon footprint throughout its entire lifecycle compared to fluorescent lamps. Although LED manufacturing processes are energy-intensive, their excellent energy efficiency and ultra-long service life result in significantly reduced overall environmental impact. Research shows that LED lighting lifecycle carbon emissions are only 30-40% of fluorescent lamps.

Waste Treatment and Recycling

Recycling and Reuse Value

Semiconductor materials, metal casings, and other components in LED lighting products have high recycling value and can be recycled through professional channels for resource reuse. Fluorescent lamps, due to mercury content, must go through hazardous waste treatment processes, with high treatment costs and significant environmental risks.

Selection Recommendations and Application Guide

Application Scenario Assessment

New Cake Display Case Recommended Solutions

For new cake display case projects, LED lighting systems are strongly recommended. Although initial investment is relatively high, from a long-term operational perspective, LED lighting shows clear comprehensive advantages in energy costs, maintenance expenses, and food preservation effects, achieving better return on investment.

It is recommended to choose warm white LEDs with color temperatures of 3000K-4000K, which can highlight the warm feeling of cakes while ensuring good color rendering effects. Power density should be controlled at 8-12W/m² to ensure adequate lighting while avoiding excessive illumination.

Existing Equipment Upgrade Strategy

For cake display cases currently using fluorescent lamps, consider gradual batch upgrades. Prioritize upgrading main display cases with high usage frequency and large customer traffic, then gradually expand to other areas. This progressive upgrade strategy can quickly obtain core benefits of LED lighting while spreading upgrade costs.

Technical Selection Key Points

Product Quality Assessment Standards

When selecting LED lighting products, focus on the following technical indicators: Color Rendering Index (CRI≥90), color temperature consistency (±200K), luminous efficacy (≥120lm/W), lifespan guarantee (≥50,000 hours), flicker index (<1%). Also choose reputable brands with good after-sales service to ensure product quality and technical support.

System Integration and Control

Modern LED lighting systems can be equipped with intelligent control functions such as time program control, brightness adjustment, and zone control. These functions can further optimize energy usage efficiency and automatically adjust lighting effects based on customer traffic at different times, enhancing user experience while reducing operating costs.

Conclusion and Outlook

Through comprehensive comparative analysis, LED lighting has significant advantages over fluorescent lighting in cake display case applications. From a technical performance perspective, LED lighting comprehensively surpasses fluorescent lamps in luminous efficacy, color rendering, and controllability; from an economic benefit perspective, although initial investment is higher, long-term operating costs are lower with better return on investment; from an environmental perspective, LED lighting meets sustainable development requirements and is a more environmentally friendly choice.

With the continuous development of LED technology and further cost reductions, LED lighting is expected to gradually become the mainstream choice for cake display case lighting. For baking industry practitioners, early adoption of LED lighting technology can not only improve product display effects and reduce operating costs, but also demonstrate corporate environmental responsibility and technological foresight, gaining more advantages in fierce market competition.

It is recommended that baking enterprises develop reasonable lighting system upgrade plans based on their actual situations, gradually achieving transformation from traditional fluorescent lamps to modern LED lighting, laying a solid foundation for sustainable enterprise development.

Post time: Jul-03-2025 Views: