Comparison on Reciprocating Compressor and Scroll Compressor

90% refrigerators are using reciprocating compressors, some large commercial refrigerators are using scroll compressors. Almost all the air conditioners are using scroll compressors. These application proportion reflects the differences between reciprocating compressor and scroll compressor. Scroll compressor is newer technology, higher efficiency, more powerful. Though, reciprocating compressor is mature technology, stable operation and low cost. The sales numbers of 2022 reflect their application difference: reciprocating compressor, 230 million units; scroll compressor, 4.7 million units (China market 2022)

Introduction of Scroll Compressor

Without suction and exhaust valves, all contact lines on the rotating scroll have a small radius of rotation, low friction speed, small loss, and high efficiency. Since the suction, compression, and exhaust processes of the scroll compressor are carried out continuously at the same time, the pressure rises slowly, so the torque variation is small and the vibration is small. At any frequency, the vibration and noise of the scroll compressor are low, because the compression process of the scroll compressor is long, the torque changes very smoothly, and the dynamic balance is very good through the secondary balance of the inertial force, so Vibration and noise levels are low. The suction, compression, and exhaust of the scroll compressor are continuously performed in one direction, directly inhaled, the harmful overheating of the inhaled gas is small, and there is no expansion process of the gas in the clearance volume, so the gas transmission coefficient is high. The scroll compressor can change its air delivery capacity by variable speed adjustment method, which is suitable for occasions where the speed changes in a wide range. The scroll compressor is a volumetric compression compressor, which is composed of a moving scroll and a static scroll. It has the advantages of small size, low noise, light weight, small vibration, low energy consumption, long life, continuous and stable gas transmission, With the advantages of reliable operation and clean air source, it is an energy-saving compressor in the world today, and is widely used in commercial air conditioners, heat pumps and refrigeration equipment. Among them, the scroll compressor, the main operating part of the scroll compressor, is only dirty and has no wear and tear, so it has a longer life, and is known as a maintenance-free compressor; at the same time, it is known as an "ultra-static compression compressor" due to its stable operation, small vibration, and quiet working environment. machine'.

Pros

- Simple structure, no reciprocating structure, less parts, less wearing parts, high reliability

- Small size, light weight, more convenient installation

- Small torque change, balanced change, small vibration

- Smooth operation, so easy to operate and easy to cooperate with automation

- High efficiency in the corresponding cooling capacity range

- Support larger displacement, corresponding to 5-15 HP refrigeration system

- Long service life, up to 20 years

- Low noise

Cons

- The manufacturing and testing of moving parts with curved surfaces is difficult and costly

- The sealing mechanism has strict requirements and the sealing structure is complex

- The compression ratio in operation is not high, suitable for air conditioning conditions

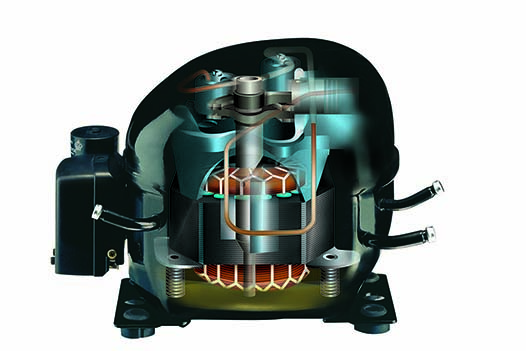

Introduction of Reciprocating Compressor

The mechanical efficiency of reciprocating compressor is generally between 0.75 and 0.9 due to the friction between the piston, piston ring, and the cylinder wall and the power to drive the lubricating oil pump. Reciprocating compressors vibrate greatly during operation. Reciprocating compressors are affected by factors such as clearance volume, suction and discharge pressure loss, heat exchange between gas and cylinder wall, and leakage. The actual gas delivery volume of the compressor is always less than its theoretical gas delivery volume. The simplest way to adjust the gas delivery of the reciprocating compressor is to run the compressor intermittently. When the system reaches the set minimum temperature, the compressor stops; when the system temperature is higher than the set maximum temperature, the compressor starts. This energy adjustment method is only suitable for small refrigerators with a power of about 10KW. For a compressor with a large capacity, the frequent start and stop of the machine will not only cause a large energy loss, but also affect the life of the machine and the stability of the voltage in the power supply circuit. normal operation of the device.

Pros

- The device system is relatively simple, the technology is mature, and the cost is low

- Low requirements on materials, easier processing, and relatively cheap cost

- The driving machine is relatively simple, most of them use electric motors, generally do not adjust the speed, and have strong maintainability

- The exhaust pressure range is wide, which can adapt to a wider pressure range and cooling capacity requirements

- Wide range of applications, the same compressor can be used for a variety of gases

Cons

- Due to the inertia of the reciprocating motion of the piston, the speed is limited

- Piston compressors with large gas delivery volume will be very bulky

- There are many wearing parts, and the vibration noise of the machine is relatively large

- The wear of the piston ring, the wear of the cylinder, etc. make the efficiency drop rapidly

- Energy consumption is larger than that of scroll compressors

- The service life is relatively short, up to about 8000 hours

- Causes airflow pulses, vibration and noise during operation

- Impulsive airflow impacts the pipe network and machine parts, which may cause damage

Read more about main types of compressors...

The Difference Between Static Cooling And Dynamic Cooling System

Compare with static cooling system, dynamic cooling system is better to continuously circulate the cold air around inside the refrigeration compartment...

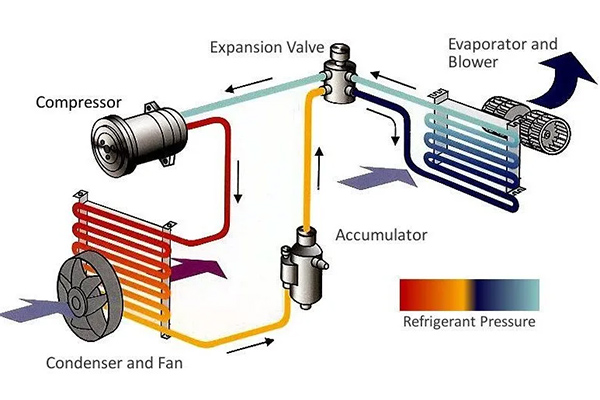

Working Principle Of Refrigeration System – How Does It Work?

Refrigerators are extensively used for residential and commercial application to help store and keep food fresh for longer, and prevent spoilage ...

7 Ways to Remove Ice from a frozen Freezer (the Last Method Is Unexpected)

Solutions to removing ice from a frozen freezer including cleaning the drain hole, changing the door seal, manual removing the ices ...

Products & Solutions For Refrigerators And Freezers

Retro-Style Glass Door Display Fridges For Beverage & Beer Promotion

Glass door display fridges can bring you something a little different, as they are designed with an aesthetic appearance and inspired by the retro trend ...

Custom Branded Fridges For Budweiser Beer Promotion

Budweiser is a famous American brand of beer, which was first founded in 1876 by Anheuser-Busch. Today, Budweiser has its business with a significant ...

Custom-Made & Branded Solutions For Refrigerators & Freezers

Nenwell has extensive experience in customizing & branding a variety of stunning and functional refrigerators & freezers for different businesses...

Post time: Oct-01-2023 Views: