In Italian culinary culture, Gelato is not just a dessert, but an art of life that integrates craftsmanship and technology. Compared with American ice cream, its characteristics of milk fat content below 8% and air content only 25%-40% create a unique rich and dense texture, with each bite concentrating the authentic flavor of the ingredients. The achievement of such quality depends not only on the selection of fresh and natural ingredients, but even more on the precise control of professional equipment. This article will systematically analyze the core technical details, standardized operating procedures, key considerations, and latest industry development trends of Italian-style ice cream display cases.

Core Configuration and Technical Details of Italian-Style Ice Cream Display Cases

The technical design of Gelato display cases directly affects the taste stability and display effect of the products. In terms of temperature, professional equipment must maintain a precise temperature control range of -12°C to -18°C. This temperature interval effectively prevents the formation of excessively large ice crystals while preserving Gelato’s soft and easy-to-scoop texture. Unlike ordinary refrigerators, high-end models such as Carpigiani’s Ready series adopt a dual-compressor independent temperature control system, enabling precise adjustment per degree Celsius to ensure that Gelato of different flavors (e.g., dairy-based and fruit-based) maintain optimal condition.

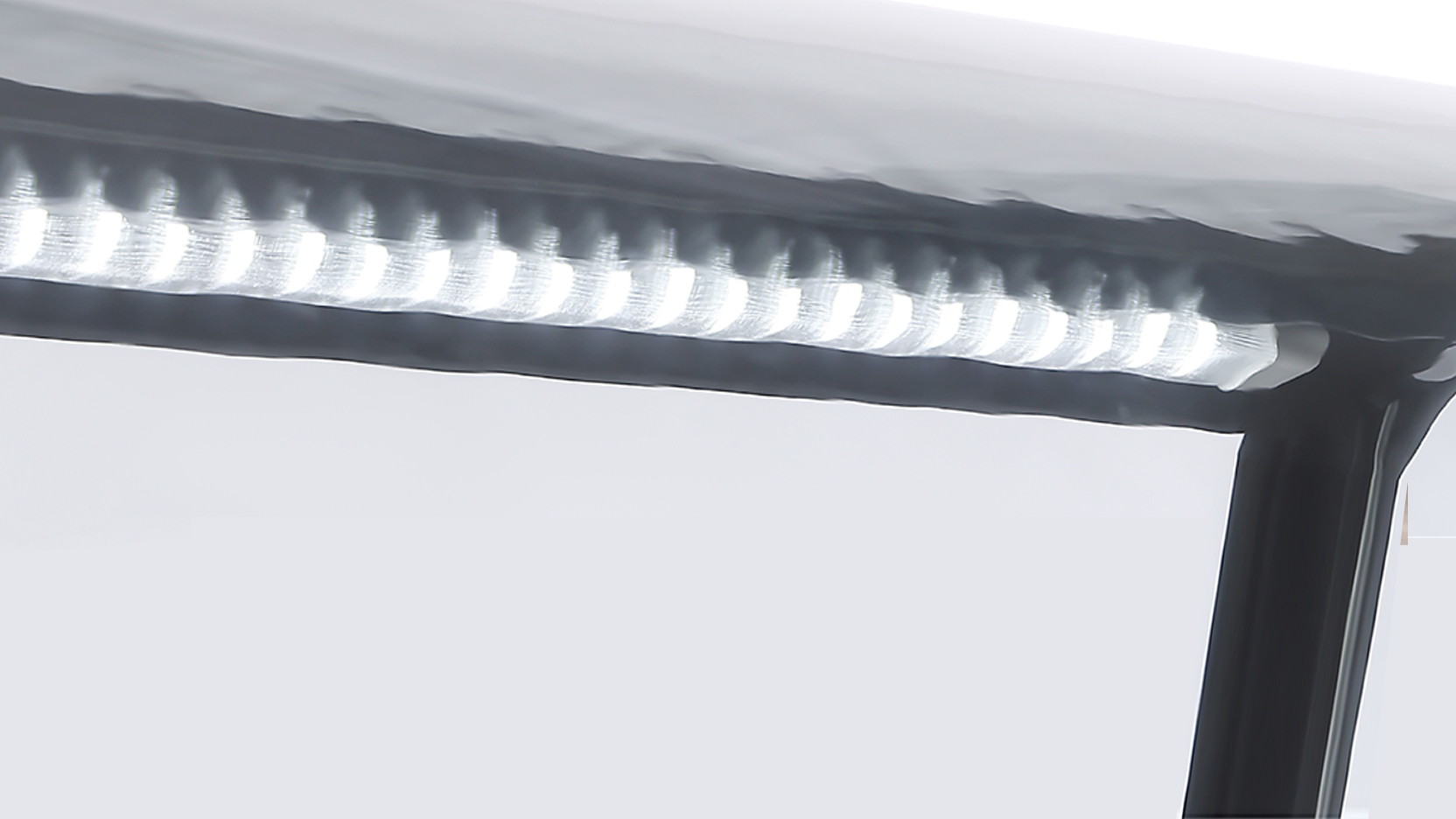

In terms of material selection, food-grade 304 stainless steel inner liners are the industry standard, offering far superior corrosion resistance and uniform thermal conductivity compared to ordinary steel, while facilitating daily cleaning and disinfection. Display cabinet doors generally use three-layer hollow anti-fog glass, which eliminates condensation through built-in electric heating wires. Combined with LED side lighting systems, they clearly showcase the natural color of Gelato. Some models are also equipped with display trays with adjustable tilt angles, which not only enhance visual layering but also align with ergonomic scooping postures.

Modern refrigeration cabinet equipment has integrated smart IoT technology. After equipping with IoT modules, devices from brands like Nenwell can achieve 24-hour remote monitoring of operating status, automatic fault alarm, and energy consumption data analysis. Carpigiani’s TEOREMA system further enables real-time viewing of parameters such as equipment temperature and operating time via mobile APP, supports remote start/stop and parameter adjustment, greatly improving store operational efficiency. Energy-saving design is equally crucial; new-type equipment adopts inverter compressors and thickened foam insulation technology, reducing energy consumption by 20%-30% compared to traditional models.

The selection of equipment capacity should match store customer flow: small dessert shops can opt for countertop models with 6-9 pan capacity, while large supermarkets or flagship stores are suited for vertical display cases with 12-18 pan capacity. Professional models typically feature an automatic defrost function, which can automatically activate during non-business hours at night, avoiding temperature fluctuations and product loss caused by manual defrosting. Some high-end equipment is also equipped with a rear refrigeration system, which automatically injects cooling capacity when the product is scooped, ensuring each scoop of Gelato maintains consistent viscosity.

Standardized Production Process and Equipment Operation Guide for Gelato

The production of Gelato is a precise scientific experiment, where every step from ingredient mixing to final shaping requires perfect coordination between equipment and craftsmanship. In the ingredient preparation stage, recipe proportions must be strictly followed. The classic milk base typically consists of fresh milk (80%), light cream (10%), white sugar (8%), and egg yolks (2%), with milk fat content controlled between 5% and 8%. For fruit-based varieties, ripe seasonal fruits should be selected, peeled and cored, then directly crushed, avoiding adding extra water to dilute the flavor.

Pasteurization is a critical step to ensure food safety and texture. Professional batch freezers such as Carpigiani’s Ready 6/9 offer two pasteurization modes: low-temperature pasteurization (65°C for 30 minutes) or high-temperature pasteurization (85°C for 15 seconds). During operation, the mixed ingredients are poured into the machine’s cylinder, and after starting the pasteurization program, the equipment uniformly heats the mixture via a spiral stirrer while monitoring real-time temperature. Upon completion of pasteurization, the machine automatically transitions to a rapid cooling phase, lowering the mix temperature to below 4°C. This process minimizes bacterial growth while promoting the stable arrangement of fat molecules.

The Aging stage requires specialized refrigeration equipment to maintain an environment of 4°C ±1°C, where the pasteurized mix is left to rest for 4-16 hours. Though seemingly simple, this step allows proteins to fully hydrate and fat particles to rearrange, laying the foundation for subsequent churning. Modern integrated equipment like the Ready series can directly complete the entire process from pasteurization to aging without transferring containers, reducing contamination risks and saving operational time.

Churning is the core step determining Gelato’s texture, where the performance of the batch freezer is crucial. After starting the equipment, the refrigerant in the cylinder walls rapidly cools the mixture, while the stirrer rotates at a low speed of 30-40 revolutions per minute, slowly incorporating air and forming fine ice crystals. Carpigiani’s Hard-O-Tronic® system displays real-time viscosity parameters via an LCD screen, allowing operators to adjust stirring intensity using up/down arrows to ensure air content is stabilized between 25%-30%. The churning process concludes when the product reaches -5°C to -8°C and assumes an ointment-like consistency.

Finished product transfer must follow the principle of “quick and steady”: use sterilized spatulas to rapidly transfer Gelato into display cases, avoiding temperature rise that causes coarse ice crystals. Each pan should be filled to no more than 80% capacity; the surface must be smoothed and the pan walls tapped to release air bubbles, then covered with food-grade plastic wrap to isolate air. After activation, display cases require 30 minutes of standing to stabilize temperature. Initial refills should use the “layered addition” method to prevent mixing of new and old products affecting taste. Before closing each day, the surface must be smoothed with a specialized scraper to form a sealing layer to prevent moisture loss.

Key Considerations for Equipment Maintenance and Production Safety

The service life of professional equipment is directly related to maintenance frequency, and establishing a scientific maintenance system can effectively reduce failure rates and operational costs. Daily cleaning is a basic requirement: after business hours, all mix pans must be removed, and the inner liner and display glass should be wiped with neutral detergent, paying special attention to cleaning residual fruit pulp or nut crumbs in corner gaps. POM material mixing scrapers need to be disassembled for cleaning, and checked for wear or deformation to ensure uniform mixing.

Weekly in-depth maintenance should be conducted, including inspecting the integrity of sealing strips, cleaning the condenser radiator filter, and calibrating temperature sensors. For equipment with self-cleaning functions, detergents must be replaced regularly according to the manual to ensure sterilization effectiveness. As the core component, the compressor should have its operating sound checked monthly for normalcy; during high-temperature summers, adequate ventilation around the equipment must be ensured to prevent ambient temperatures exceeding 35°C from affecting refrigeration efficiency.

Improper raw material storage directly impacts product quality and equipment lifespan. Fresh fruits should be refrigerated and used within 48 hours; opened cream must be sealed and refrigerated, with usage completed within 3 days. Sugars and powdered ingredients need to be stored in sealed containers in dry areas to prevent moisture absorption and caking, which could block equipment feed inlets. Special attention should be paid to avoiding long-term placement of ingredients containing alcohol or high acidity in display cases, as such substances may corrode the stainless steel inner liner and affect refrigeration performance.

Operational safety cannot be overlooked: during equipment operation, ventilation openings must remain unobstructed, and placing debris on top of the machine is prohibited. Before cleaning or maintenance, the power supply must be disconnected, and operations should only proceed after the mix cylinder is completely thawed. Equipment from brands like Carpigiani is designed with rounded corner protection and emergency stop buttons, effectively reducing the risk of operational accidents. Operators must receive regular hygiene training and strictly implement hand washing and disinfection procedures to avoid direct contact with products using bare hands.

Basic troubleshooting skills should be mastered: if display case temperatures fluctuate excessively, check for aging sealing strips or loose door hinges; weak churning in batch freezers may result from worn scrapers or loose motor belts; coarse product texture is often caused by insufficient aging time or excessive churning temperatures. Establishing an equipment operation log to record daily temperature curves and production data helps in timely detection of abnormalities and early warning.

Technical Trends and Innovation Directions in the Industry

Healthy consumption trends are driving the development of Gelato equipment towards greater precision and versatility. The growing demand for low-sugar and low-fat products is propelling equipment upgrades; new-generation batch freezers can adjust stirring speeds and temperature curves to maintain optimal texture while reducing sugar content.

Intelligence is an irreversible development trend. Next-generation equipment integrates AI algorithms to automatically adjust stirring intensity and refrigeration capacity based on ingredient formulas. Carpigiani’s 243 T SP model features 8 automatic programs covering different categories such as milk-based and fruit sorbet, and can even precisely produce shaped ice cream cakes. Remote diagnostic systems have reduced after-sales service response time from the traditional 24 hours to within 4 hours, significantly minimizing downtime losses.

The concept of sustainable development has spurred green equipment design. Major brands have adopted environmentally friendly refrigerants and energy-efficient compressors, with some models further reducing carbon footprints through solar-assisted power supply systems. Equipment materials are also moving towards recyclability; companies like Carpigiani have begun using recycled stainless steel for non-contact components while simplifying structural design to facilitate later disassembly and recycling.

Market segmentation has led to equipment diversification. Compact equipment for small entrepreneurs occupies less than 1 square meter yet completes the entire process from pasteurization to churning. High-end flagship stores, on the other hand, favor customized display cases that create immersive experiences with lighting and styling. The rise of mini home-use models also merits attention; these devices simplify operational procedures while retaining core temperature control technology, allowing consumers to make professional-grade Gelato at home.

Nenwell Gelato display cases have always centered on the two core principles of “stable quality” and “efficiency improvement”. From intelligent production lines to continuous technological innovation, they never cease to create value.

Post time: Sep-17-2025 Views: