In the beverage retail scenario, the noise level of the LSC series single-door refrigerated vertical cabinet has evolved from a “secondary parameter” to a core indicator influencing purchasing decisions. According to the 2025 industry report, the average noise value in the commercial freezer market has dropped from 45 decibels five years ago to 38 decibels. 72% of convenience store and catering establishment buyers list silent performance as their top consideration.

Noise Limits for Refrigerating Appliances:

| Nominal Total Volume / L | Noise Limit of Direct-cooled Refrigerators and Direct-cooled Refrigerator-freezers / dB(A) | Noise Limit of Frost-free Refrigerators and Frost-free Refrigerator-freezers / dB(A) | Noise Limit of Freezers / dB(A) |

|---|---|---|---|

| ≤300 | 45 | 47 | 47 |

| >300 | 48 | 52 |

The dual-driven forces of policy and technology have accelerated the silent upgrade. On one hand, the new national standards have tightened the noise limits for commercial refrigeration equipment, clearly stipulating that the operating noise of single-door beverage refrigerated vertical cabinets should be controlled below 42 decibels. On the other hand, the popularization of variable frequency technology and intelligent noise reduction structures has continuously lowered the cost threshold for low-noise equipment. Nenwell has made 38 decibels the standard for its core equipment, and some high-end models even reach the “library-level” silent standard of 35 decibels. The LSC series is a representative product born in this trend.

I. Multidimensional Hazards of Noise in Refrigerated Vertical Cabinets

The negative impact of noise on commercial scenarios far exceeds “auditory discomfort” and has become a non-negligible operating cost. From the perspective of customer experience, a survey of a convenience store shows that when the noise of the refrigerated cabinet exceeds 40 decibels, the average customer dwell time is shortened by 23%, and the repurchase rate drops by 15%. Continuous buzzing can trigger subconscious irritability, especially in boutique retail stores that emphasize experience.

For employees, the health risks of long-term exposure to noisy environments deserve more attention. Research by the World Health Organization (WHO) shows that long-term exposure to environments above 45 decibels can lead to issues such as increased hearing thresholds and inattention. Convenience store clerks are exposed to the noise of refrigerated cabinets for more than 8 hours a day. If the equipment is not soundproofed, the probability of occupational hearing damage is three times higher than that of the general population.

Noise can also serve as an “early warning signal” for equipment failures. The noise of a normally operating refrigerated cabinet is characterized by stable low-frequency sounds. If sharp abnormal noises or intermittent roars suddenly occur, it often indicates problems such as compressor cylinder jams or fan bearing wear. Data from a catering chain shows that 80% of refrigerated cabinet failures are preceded by abnormal noise, and the annual loss of beverage spoilage due to ignoring noise signals amounts to tens of thousands of yuan.

II. Tracing the Source: Five Core Sources of Noise in Refrigerated Vertical Cabinets

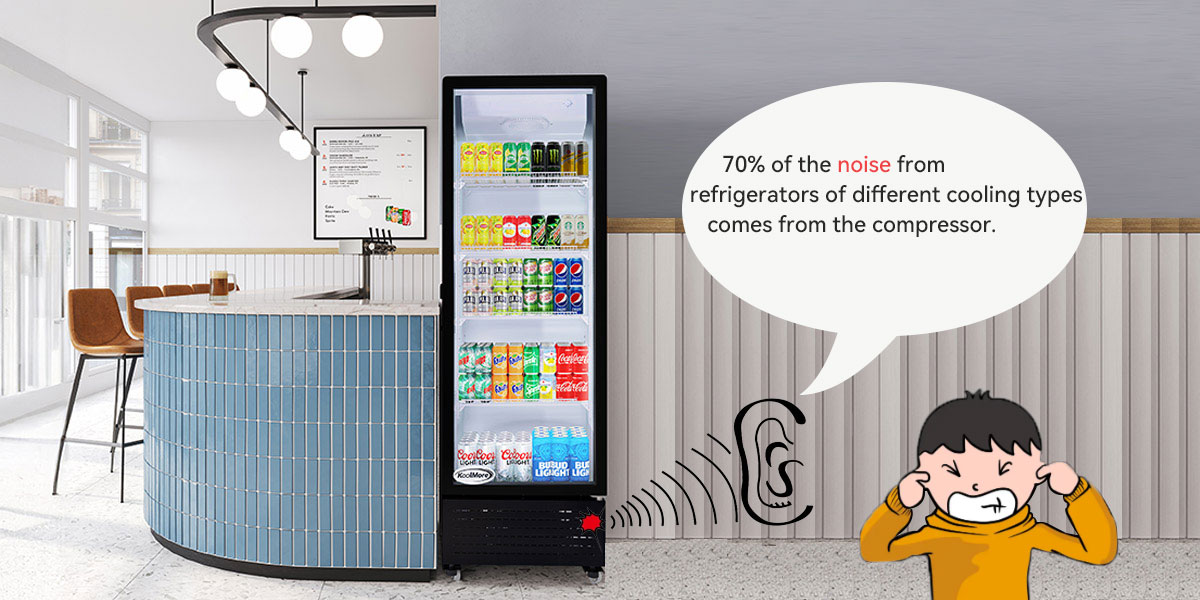

1. Compressor: The “Dominant Contributor” to Noise

As the “heart” of the refrigeration system, the operating noise of the compressor accounts for more than 70% of the total equipment noise. When a fixed-frequency compressor starts and stops, the mechanical impact between the piston and the cylinder generates instant high noise. Even during stable operation, the electromagnetic noise and vibration transmission of the motor operation create continuous interference. If the compressor is not shock-absorbed during installation, the vibration will be amplified through the cabinet, resulting in “resonant roaring.”

2. Fans and Air Ducts: Overlooked Sources of Aerodynamic Noise

The operation of fans in air-cooled refrigerated vertical cabinets generates two types of noise: one is the vortex noise formed by the blades cutting through the air, and the other is the turbulent noise caused by the friction between the airflow and the air duct walls. Experiments by Shanghai Jiao Tong University have found that if the gap between the fan blade tip and the air duct is not properly designed, it will cause air backflow, increasing the noise sound power by 15%. After optimization, the noise at specific measurement points can be reduced by 5.79 decibels. The 3D circulation air duct adopted by the LSC series is precisely an optimized design for this problem.

3. Refrigerant Flow: “Abnormal Sounds” Prone to Misjudgment

When the refrigerant circulates in the pipeline, if the bending radius of the pipeline is too small or blocked, it will produce a “gurgling” flow noise. This noise is particularly noticeable at the initial stage of equipment startup and is often misjudged as a fault by users. In addition, abnormal refrigerant pressure can cause pipeline vibrations, resonating with the cabinet and producing low-frequency noise.

4. Cabinet Structure: The “Resonant Cavity” That Amplifies Noise

If the cabinet is made of low-strength materials such as thin steel plates, the vibrations of the compressor and fan will excite the cabinet’s resonance, amplifying the noise by 2-3 times. In some products, due to loose pipeline fixing, the pipeline collides with the cabinet during operation, producing intermittent “tapping” noises. Although the decibel level of this noise is not high, its harshness far exceeds the smooth operation sound.

5. Installation and Environment: Post-installation Noise Inducers

An uneven floor is the most common post-installation noise source. When the refrigerated cabinet is placed at an angle, the compressor base is unevenly stressed, intensifying the vibration noise. If the cabinet is placed close to walls or other equipment, the noise will be superimposed through solid conduction and reflection, making the measured value 3-5 decibels higher than in a standard environment. In addition, placing items on the top creates a “resonator,” converting the equipment’s vibrations into obvious abnormal noises.

III. Full-chain Noise Reduction: Systematic Solutions from Design to Use

1. Silent Design of Core Components

The selection of the compressor is the foundation of noise reduction. If the LSC series uses a variable frequency compressor, it can avoid frequent starts and stops by adjusting the rotation speed, reducing the operating noise by 8-10 decibels. Paired with bottom shock-absorbing pads and suspended brackets, it can reduce 90% of vibration transmission. The fan should adopt a silent model with optimized blade curvature, with the blade tip gap controlled within 0.5 millimeters. At the same time, through an intelligent speed control system, the rotation speed can be automatically reduced at night.

2. Acoustic Optimization of Cabinets and Air Ducts

Honeycomb-shaped sound-absorbing cavities and high-density sound-insulating cotton should be installed inside the cabinet. This structure can absorb more than 30% of mechanical noise. The compressor compartment adopts a multi-chamber sound-absorbing design, and the opening can be automatically controlled according to the noise value through adjustable sound-absorbing holes, balancing noise reduction and heat dissipation efficiency. The anti-fog tempered glass door of the LSC series not only enhances the display effect, but its sandwich structure can also block some internal noise from spreading outward.

3. Standardized Installation and Debugging Processes

During installation, a level should be used to calibrate the cabinet to ensure uniform force on all four corners. Rubber shock-absorbing pads should be added to the base when necessary. A distance of 10-15 centimeters should be maintained between the cabinet and the wall to avoid noise reflection. If placed on easily resonant surfaces such as wooden floors, sound-insulating pads can be laid to cut off vibration transmission. During the debugging phase, the fixing of the pipelines should be checked, and buffer rubber sleeves should be added to loose parts.

4. Noise Control Techniques for Daily Maintenance

The fan blades should be cleaned weekly to prevent dynamic balance disorders caused by dust accumulation. A 1-gram accumulation of dust on the blades can increase the noise by 3 decibels. The compressor fasteners should be checked monthly, and loose screws should be tightened in a timely manner. The fan bearings should be lubricated quarterly to reduce friction noise. When “gurgling” abnormal sounds are detected, refrigerant leakage or pipeline blockage issues should be promptly investigated to prevent the problem from worsening.

5. Dynamic Noise Reduction of Intelligent Systems

High-end models can be equipped with sound sensors and intelligent control systems to monitor noise values in real-time. When the noise exceeds 38 decibels, it automatically reduces the compressor speed or adjusts the fan gear. If the LSC series has a night energy-saving mode, the temperature control range can be widened during non-business hours, reducing the equipment’s operating load and consequently decreasing the noise by 5-6 decibels.

Post time: Sep-28-2025 Views: