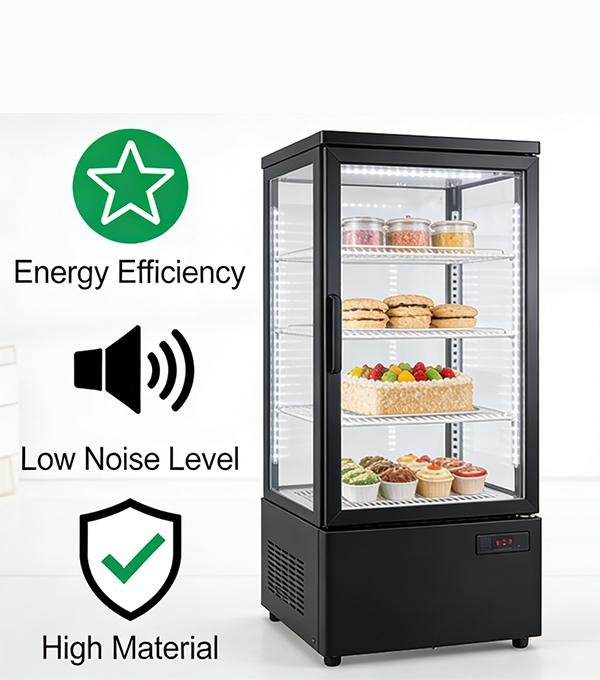

“Just bought a small countertop cake display case, but after three months the cooling became unstable—mousse softened after just one day.” “The glass fogs up, obscuring the cakes. Wiping it clears it only for it to fog again, killing customers’ desire to buy.” “The compressor noise is so loud it ruins the customer experience, and no one from after-sales even bothers to address it”… Many dessert shop and coffee shop owners have encountered quality pitfalls when selecting compact countertop cake display cases. We can approach these issues from multiple angles.

For small-scale shops, compact countertop cake display cases aren’t just about aesthetics—they’re critical equipment for preserving dessert quality. Their performance directly impacts ingredient freshness, customer experience, and operational costs. Yet the market is flooded with mixed-quality products, and low-cost, subpar options abound. How can you ensure quality from sourcing to daily operation? Below, we break down the professional logic into plain language across five core dimensions to help you select and utilize this “profit-generating tool” effectively. I. Core Components: The ‘Heart’ and “Framework” of Quality—These 3 Elements Are Critical The foundation of equipment quality lies in its core components. The performance of a compact countertop cake display cabinet hinges entirely on these three key areas.

1. Core Components: The “Heart” and ‘Framework’ of Quality—These 3 Points Are Key

The foundation of a unit’s quality lies in its core components. The performance of a small countertop cake display cabinet relies entirely on these three major parts, each of which must be meticulously inspected during selection.

First is the compressor—the “heart” of the cake display cabinet—which directly determines cooling efficiency, noise levels, and service life. Premium models typically feature imported compressors from brands like Danfoss or Embraco, paired with all-copper evaporator and condenser coils. This configuration ensures rapid, stable cooling while resisting corrosion in humid environments, extending service life by 3-5 years compared to standard units. Conversely, budget models often use generic compressors that deliver uneven cooling, are prone to malfunctions, and incur high maintenance costs.

Second is the cooling and humidity control system. Cakes are sensitive to temperature and humidity. Premium models feature intelligent microprocessor temperature controllers that precisely maintain optimal preservation temperatures between 2-10°C. Some high-end units also include ultrasonic humidifiers to sustain ideal humidity levels of 70%-90%, preventing cakes from drying out and cracking. Prioritize air-cooled models, which use multidimensional airflow channels for even cooling distribution and automatic defrosting. These are more hassle-free than direct-cool models and prevent frost buildup that compromises freshness. Lastly, consider display glass and cabinet materials. Opt for double-layered tempered glass with automotive windshield-grade hardness for shatter and impact resistance. Its hollow design reduces heat transfer for superior insulation. Models with front glass featuring silver paste coating and electric defogging prevent fogging that obscures visibility. Pairing this with warm-toned LED lighting enhances cake presentation. For the cabinet exterior, 304 stainless steel is recommended for its corrosion resistance and ease of cleaning. Interior shelves should prioritize aluminum alloy or chrome-plated materials, which offer strong load-bearing capacity and rust resistance. Additionally, they must comply with the GB 4806.9-2016 standard for metal materials in food contact to prevent ingredient contamination.

II. Safety Certifications: The “Passport” to Quality—Don’t Buy Without Them

Reputable small countertop cake display cabinets must pass authoritative safety certifications, which are the baseline for ensuring operational safety and food hygiene.

First, verify whether the product holds CQC Food Machinery Safety Certification. This certification requires multiple stages, including type testing and factory inspections, ensuring compliance with standards such as GB 16798-1997 “Food Machinery Safety and Hygiene” and GB 5226.1-2008 “Electrical Safety of Machinery”. Second, verify electrical safety certification. Models compliant with the GB/T 4706 series standards prevent hazards like electric leakage and overheating.

Additionally, all food-contact components—such as shelves and inner liners—must carry a declaration of conformity for food-contact materials. This clearly states that materials meet relevant food safety standards: stainless steel must comply with the 06Cr19Ni10 standard, while coatings must meet GB 4806.10-2016. Models lacking these certifications are likely OEM products from small factories, offering no guarantee of quality or safety.

III. Factory Testing: The “Final Line of Defense” for Quality—These Tests Are Essential

Premium brands conduct rigorous testing before products leave the factory, which is crucial for preventing defective items from entering the market. When purchasing, proactively ask the seller whether the product has undergone these core tests:

First, door fatigue testing: Premium models undergo over 200,000 door-opening cycles to ensure stable door sealing, preventing cold air loss and reduced cooling efficiency due to leaks. Second, continuous high-temperature testing simulates prolonged operation in summer heat to verify compressor and refrigeration system stability. Third, noise testing: Laboratory calculations optimize airflow design to keep operational noise below 45 decibels, maintaining a quiet store environment.

In contrast, low-cost models often skip these testing phases. Their doors warp and leak cold air within months, while compressors frequently shut down in high temperatures, severely compromising user experience.

IV. Brand and After-Sales Service: The “Ongoing Assurance” of Quality—Don’t Sacrifice This for Price

Choosing the right brand and after-sales support prevents numerous headaches during use. Prioritize brands with strong market reputations and formal production certifications, such as Aokema or Xinmai. These brands not only offer more stable product quality but also maintain more comprehensive after-sales systems.

When purchasing, confirm the warranty period. High-quality models typically offer over 2 years of warranty, with core components like compressors covered for 3-5 years. Simultaneously, verify the availability of a localized after-sales team to ensure rapid response and repairs when equipment malfunctions. Many businesses opt for cheaper, unbranded models to save money upfront. However, when these fail, finding support becomes impossible, forcing a replacement purchase that ultimately increases operational costs.

V. Proper Usage: The “Crucial Step” for Extending Lifespan – Key Details to Note

Even high-quality equipment requires proper operation to maintain long-term stability. Ensure adequate ventilation around the unit, keeping it away from heat sources and direct sunlight to prevent compressor overload. Minimize frequent door openings—bulk restocking reduces cold air loss. Perform regular maintenance: wipe shelves and glass weekly, check for blocked vents monthly, and schedule annual professional refrigeration system inspections.

Additionally, adjust temperatures based on dessert types: refrigerated items like mousses and mille-feuilles require 2-6°C; room-temperature cakes stored short-term can be set at 8-10°C. Avoid extreme temperatures that compromise texture and flavor.

Core Logic of Quality Assurance

Quality assurance for compact countertop cake display cabinets fundamentally relies on end-to-end control encompassing “core components + safety certifications + factory testing + brand after-sales support + proper usage.” Businesses should avoid blindly pursuing low prices, instead prioritizing models with premium core components, comprehensive certifications, and robust after-sales service, while also maintaining diligent daily operation and upkeep.

A high-quality compact countertop cake display cabinet not only preserves dessert freshness and boosts customer appeal but also reduces repair costs over time, ultimately saving money. By filtering through the five dimensions outlined above, you can avoid most quality pitfalls and select premium equipment suited to your shop’s needs.

Post time: Dec-25-2025 Views: