Commercial glass – door upright cabinets refer to display cabinets for beverages, alcoholic drinks, etc. With a glass – door panel design, they are commonly seen in shopping malls, supermarkets, convenience stores, etc. In terms of volume, they are divided into single – door and multi – door types. Multi – door cabinets have a large volume and wide space, capable of accommodating more food storage. These upright cabinets use air – cooled refrigeration, which can prevent frost and ice formation inside the cabinet. The temperature remains around 2 – 8°C all year round.

The following is an interpretation of the important parts of commercial glass – door upright cabinets:

The fan system refers to a tool that relies on a fan as the core heat – dissipation or refrigeration – assisting system. Its working logic is different from that of traditional direct – cooling refrigerators. The fan creates a forced air circulation inside the refrigerator, accelerating the flow and distribution of cold air in the cabinet, reducing the temperature difference in different areas, and making the refrigeration more uniform.

Most upright cabinets are air – cooled or a combination of air – cooled and direct – cooled refrigerators. They rely on the fan to drive the circulation of cold air and do not require manual defrosting (the fan blows the frost on the evaporator to melt and discharge it). The combination type combines the advantages of fast refrigeration of direct – cooling and uniform heat – dissipation of the fan.

The advantages are obvious. The refrigeration efficiency is relatively high, and the temperature stability is good. It is suitable for storing temperature – sensitive ingredients and can reduce the trouble of manual defrosting.

It should be noted that the fan operation may generate slight noise, and due to air circulation, ingredients are prone to drying out due to water loss. Usually, it needs to be used in conjunction with a moisture – retaining drawer.

The upright cabinet casters are small rolling components installed at the bottom of the equipment. Their main function is to facilitate the movement and position adjustment of the refrigerator. Their design usually takes into account the load – bearing capacity, which needs to match the weight of the refrigerator itself to ensure stability and no shaking during movement. They are equipped with a braking function (such as a brake device), which can be locked after positioning to prevent accidental sliding and ensure safe use.

In terms of materials, wear – resistant and corrosion – resistant rubber is mostly used, which can not only reduce the wear on the ground but also adapt to humid environments such as kitchens and extend the service life. Structurally, it is generally combined with the support components at the bottom of the upright cabinet, taking into account both the convenience of movement and the stability when placed.

The upright cabinet plug is a key component that connects the refrigerator to the power socket. Its main function is to introduce the mains power into the refrigerator to supply power to components such as its compressor and control system.

Structurally, it is a three – pin plug. Two of the pins are the live wire and the neutral wire, responsible for transmitting electrical energy. The third pin is the ground wire, which is connected to the metal shell of the refrigerator. In case of leakage of the upright cabinet, the current can be led into the ground to avoid electric shock to the human body and ensure safe use.

The rated current of the plug is matched with its power (generally, for equipment with a relatively small power, the rated current of the plug is about 10A). The material is plastic with good temperature resistance and insulation. The internal metal inserts are made of copper materials with excellent electrical conductivity to ensure stable current transmission.

We need to note that during use, it is necessary to ensure good contact between the plug and the socket to avoid problems such as poor contact and heating caused by looseness.

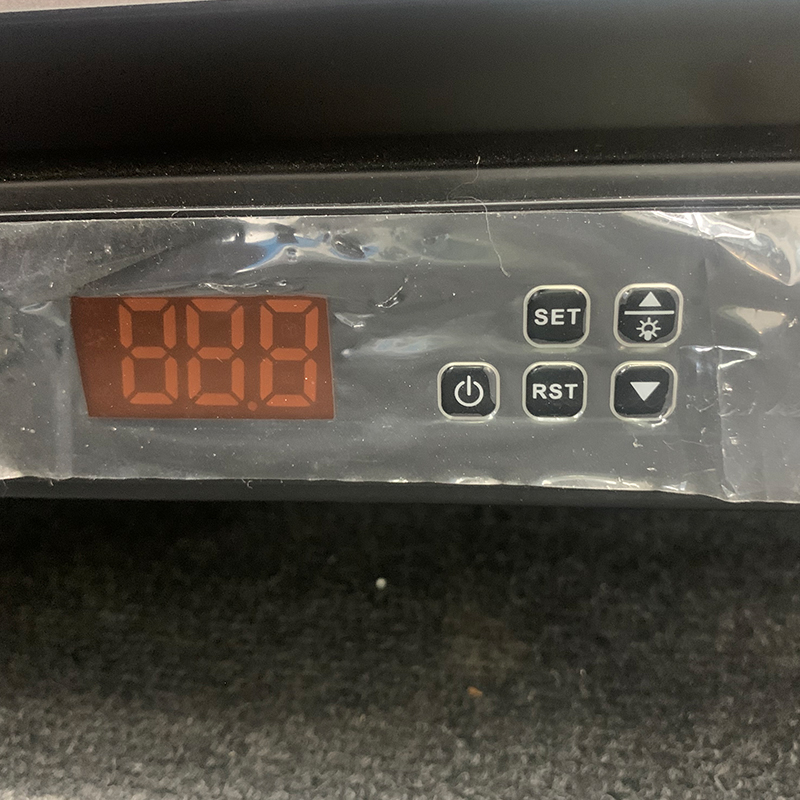

Each commercial upright cabinet is equipped with a complete power switch, temperature adjustment button, light button, and temperature display screen. According to different brands, different design methods are adopted. High – end ones mostly adopt a touch – screen design, which looks high – end, but the price is much more expensive than that of mechanical designs. If it breaks down, the maintenance cost is also very high. Therefore, most are designed as mechanical buttons, which not only have a long service life but also are convenient to replace switch components. Importantly, they are all designed with waterproof, insect – proof, etc. features. There is a dust – proof net inside and a waterproof cover outside.

This issue introduces these three points. In the next issue, we will introduce important components of the upright cabinet such as the compressor and the cooler.

Post time: Jul-15-2025 Views: