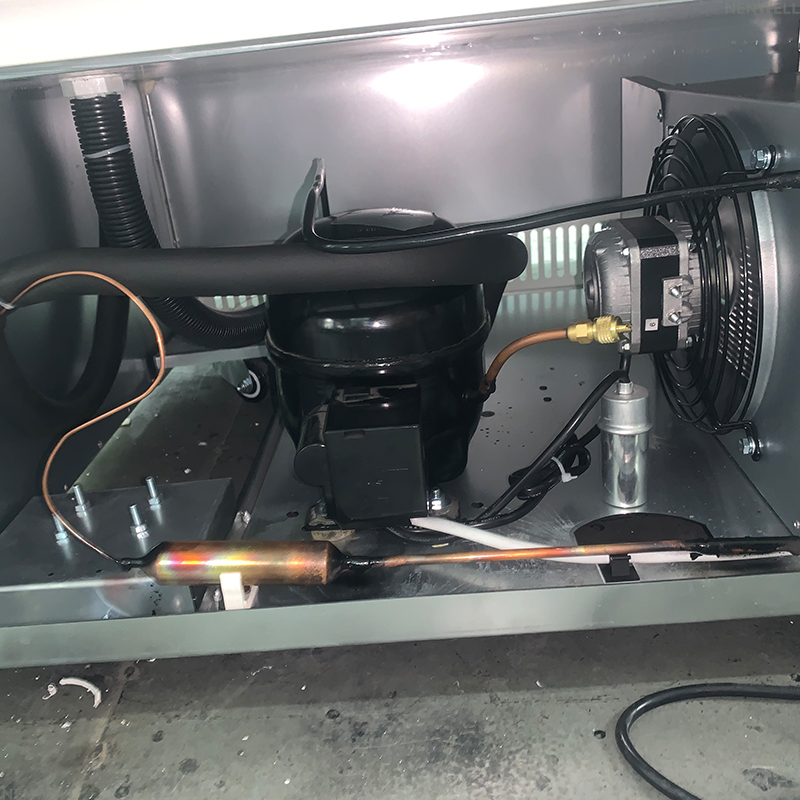

In the first phase of the commercial refrigerated upright cabinet, we interpreted the fan, power switch, casters, and power plug. In this phase, we will interpret important components such as the compressor and condenser, and pay attention to matters during the use process.

The compressor is the core equipment of the refrigerated upright cabinet. Its core function is to drive the refrigeration cycle and maintain a low – temperature environment inside the cabinet. Specifically, it sucks in the low – temperature and low – pressure refrigerant vapor in the evaporator, compresses it to turn it into high – temperature and high – pressure vapor. This process increases the energy level of the refrigerant, enabling it to release heat to the outside in the condenser. Subsequently, the refrigerant is depressurized and cooled by the throttling device, enters the evaporator to absorb the heat inside the refrigerated upright cabinet, and completes the refrigeration cycle.

Simply put, the compressor is like the “heart” of the refrigerated upright cabinet. By continuously compressing the refrigerant, it promotes its circulation within the system, thus continuously transferring the heat inside the cabinet to the outside, ensuring that the temperature inside the cabinet is stably maintained within the set low – temperature range and achieving the refrigeration and preservation function of food ingredients and other items. If the compressor malfunctions, the refrigeration cycle is interrupted, and the refrigerated upright cabinet can no longer maintain a low temperature and loses its refrigeration function.

The condenser is an important hub for energy transfer. As a heat – exchange device, it plays the role of a “hub” in energy transfer. The core lies in achieving efficient heat transfer through the state change of the medium (such as refrigerant, water, etc.). Its working principle is as follows: High – temperature and high – pressure gaseous working medium (such as the refrigerant in an air – conditioner) enters the condenser, comes into contact with the external low – temperature medium (air or cooling water), releases heat through methods such as heat conduction and convection, and condenses into a liquid state. In this process, the thermal energy of the working medium is transferred to the low – temperature medium, completing the energy transfer from the “high – temperature end” to the “low – temperature end”.

For example, in equipment such as refrigeration systems and steam power plants, the condenser is the “outlet” for the working medium to release heat and also the energy “transfer point” for subsequent cycles (such as refrigerant throttling and depressurization, steam condensation and return of water). It ensures the orderly flow of energy in different links and is a key component for maintaining the energy balance and efficient operation of the system.

Of course, commercial upright cabinets usually do not use direct cooling. Most of them combine air – cooling to make the temperature inside the cabinet uniform because direct cooling can cause problems such as icing and frosting. Therefore, for refrigerating beverages like cola, air – cooling can completely solve the problem. For deep – frozen items such as meat products, direct cooling is required. However, the choice should be based on the actual usage scenario. Nenwell states that the choice should be based on the actual purpose. In the case of high demand, customization is the best choice to ensure optimal power and reduce costs.

What issues need to be noted?

In the case explanation of the first phase, we mentioned the common maintenance matters of upright cabinets and also briefly described the selection skills. The following points need to be noted in this phase:

How to maximize the efficiency of beverage upright cabinets

During the use process, master the core planning skills. In terms of space utilization, use adjustable shelves, adjust the quantity seasonally, and place beverages in layers. Set the golden line position for placement to improve the picking efficiency. In terms of refrigeration efficiency, set an appropriate temperature to avoid excessive energy consumption and waste of resources. Follow the first – in – first – out principle for inventory use to avoid long – term backlogs and slow – moving products. These need to be adjusted flexibly to maximize efficiency.

Be cautious in model selection

Different models of upright cabinets have different power consumption. If the preliminary stage operating cost is high, an appropriate model of commercial upright cabinet should be selected according to the actual situation. For example, when the sales volume is not large, choose a small – capacity beverage cabinet model, and for large – size ones, one can be selected as a backup. Of course, appearance is also very important as it can attract more users. Although the functions of some refrigerated cabinet models are average, their craftsmanship is perfect and their appearance is beautiful, which is also an important consideration.

The importance of brand selection

Although Nenwell is not the largest global brand manufacturer, relying on years of manufacturing and trading experience, the quality of its refrigeration equipment is widely recognized. At the same time, it has a good understanding of the needs of users in most regions of the world and provides a variety of solutions for different user needs, creating greater value for users. Therefore, you need to note that those without brand certification should not be selected. Some local upright cabinets attract customers with price advantages, but their quality and service are poor, which will bring a very bad experience.

Pay attention to understanding the supplier

There are many global refrigeration equipment suppliers, and well – known brands include Midea, Haier, Gree, Panasonic, etc. The key problem is that many fake well – known brands exist, and this phenomenon is very serious. Therefore, it is necessary to pay attention to understanding the supplier, especially when batch customization is required. It is best to conduct on – site inspections, and subsequent negotiations will depend on the actual needs and interests.

This is the end of this phase’s content. We mainly explained the core refrigeration components of the upright cabinet left over from the previous phase, put forward important points for attention in brand and supplier selection, and analyzed the usage efficiency skills. We hope this can help you.

Post time: Jul-16-2025 Views: