Cake display cabinets are essential equipment in bakeries, cafes, and dessert shops. Beyond their basic role of showcasing products, they play a crucial part in preserving the quality, texture, and visual appeal of cakes. Understanding their functions, types, and key parameters can help both businesses and consumers appreciate their importance,It is necessary to master important indicators such as temperature, humidity, refrigeration method, and energy efficiency rating.

1. Core Functions of Cake Display Cabinets

Cakes are delicate products sensitive to temperature and humidity. Without proper storage, cream can melt, cake layers can dry out, and fruits can lose freshness. A high-quality cake display cabinet addresses these issues through:

- Temperature Control: Maintaining a stable low temperature (typically 2–8°C) slows bacterial growth and prevents cream melting . According to the International Dairy Federation, cream-based products stored at temperatures above 10°C have a shelf life reduced by up to 50%.

- Humidity Regulation: Keeping humidity levels between 60%–80% prevents cake dehydration and surface cracking. The American Bakers Association notes that humidity fluctuations greater than 15% can significantly affect cake texture.

- UV Protection: Many models use tinted glass to block harmful UV rays, which can fade food colors and degrade nutrients.

2. Common Types of Cake Display Cabinets

2.1 Vertical Cake Cabinets

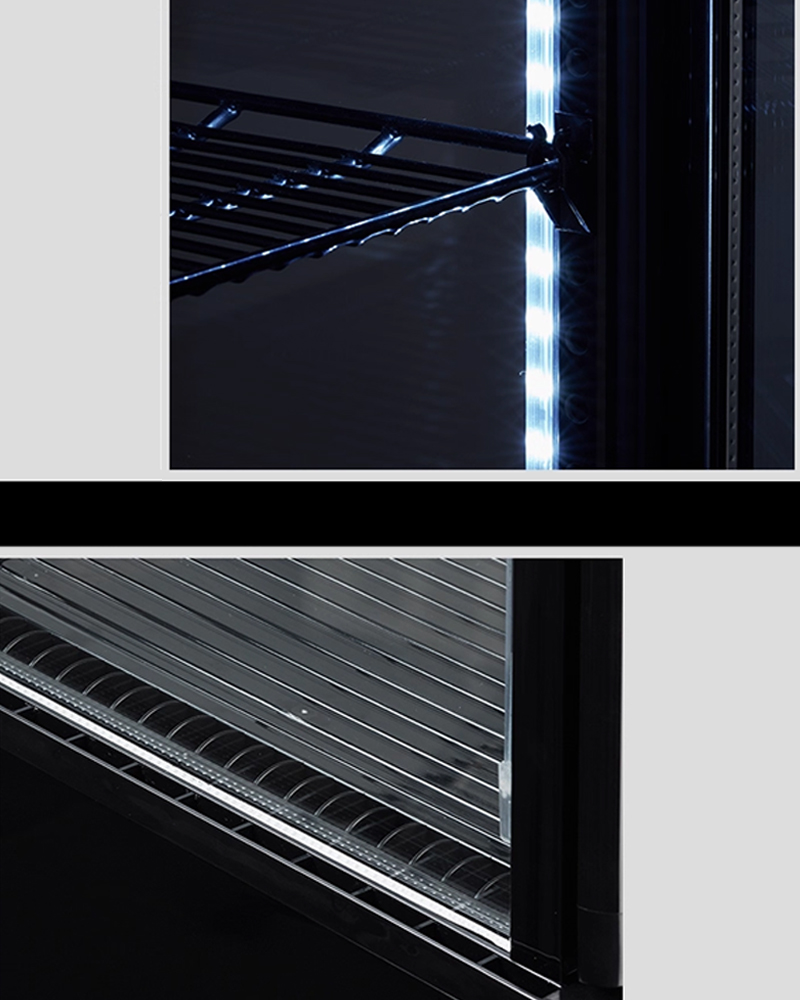

As shown in the image, vertical cake cabinets are tall, freestanding units with multiple shelves. They are ideal for stores with limited floor space but a large variety of cakes. Key features include:

- Space-efficient design maximizing vertical storage.

- Double-layered anti-fog glass doors to maintain visibility while insulating cold air.

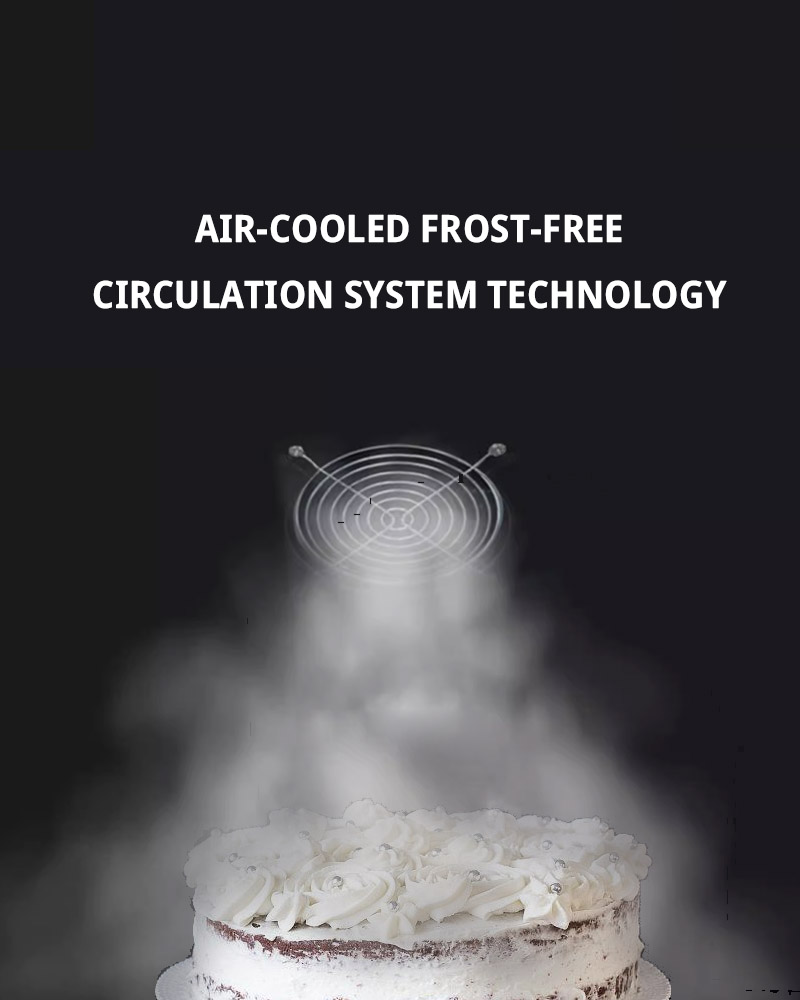

- Forced-air cooling systems ensuring uniform temperature across all shelves (temperature variation within ±1°C, per European standards).

2.2 Countertop Cake Cabinets

Compact and placed on counters, these are suitable for small cafes or showcasing bestsellers. They offer precise temperature control but have smaller capacities, typically holding 4–6 cake slices.

2.3 Open-Top Cake Cabinets

Without doors, these cabinets allow easy customer access. They rely on powerful air curtains to maintain temperature—effective models can keep internal temperatures stable even in warm store environments, with energy loss rates below 20% (tested by the China Refrigeration Institute).

3. Key Parameters to Consider

3.1 Temperature Range and Precision

Different cakes require specific temperatures: Mousse cakes: 3–5°C (due to high cream content) Cheesecakes: 2–7°C Fruit tarts: 4–8°C (to preserve fruit freshness) A good cabinet should maintain set temperatures with a precision of ±0.5°C.

3.2 Energy Efficiency

Look for cabinets with energy efficiency ratings (e.g., EU Energy Class A++). A 300L vertical cabinet with Class A++ rating consumes approximately 500 kWh/year, 30% less than a Class B model, according to the European Committee for Standardization.

3.3 Material Quality

Interior shelves should be food-grade stainless steel (resistant to corrosion from cake acids). Glass doors should be tempered for safety and have low-emissivity coatings to reduce heat transfer.

4. Maintenance Tips for Longevity

Proper maintenance ensures optimal performance: Clean interior surfaces daily with mild detergent to prevent bacterial buildup. Dust condenser coils monthly (dirty coils can increase energy consumption by 25%, per the U.S. Department of Energy). Check door seals quarterly for cracks—damaged seals can cause 15–20% cold air loss. Calibrate temperature settings annually using a professional thermometer.

Cake display cabinets are more than just storage units—they are guardians of quality, ensuring that every cake reaches customers in its best condition. Whether you’re a business owner selecting equipment or a customer admiring a beautifully displayed dessert, understanding these details adds a new layer of appreciation for the technology behind the sweets.

Post time: Sep-05-2025 Views: