How to repair the leaking pipeline of the refrigerator?

The evaporators of these refrigerators are generally made of non-copper pipe materials, and mildew will appear after a long period of use. After checking the leaking pipe parts, the usual repair method is to replace the damaged pipe parts with new ones. of the coil. So how to check the location of the refrigerant leak in the refrigerator before the maintenance work of the replacement parts starts?

How to judge the refrigerant leak of the refrigerator?

If the upright refrigerator is not cooling, after starting the machine for dozens of minutes, touch the high-pressure pipe and feel hot; at the same time, the low-pressure pipe is close to room temperature (normally it should be around 0°C, with slight frost), which can be judged as the fault of the refrigerator. Refrigerant leaks.

How to define the scope of leakage?

Generally, refrigerant leakage of refrigerators will occur in these accessories: main evaporator, auxiliary evaporator, door frame heating tube, built-in condenser and other places.

How to test pipelines with compressed air?

Unreliable way to check for leaks:

Inexperienced maintenance engineers directly connect the pressure gauge to the process pipe of the compressor, add dry air to 0.68MPa, and test the pressure of the external pipeline of the refrigerator. This method is sometimes futile, because the compressor, condenser, evaporator and other pipeline fittings are connected together, the pipelines communicate with each other, and the gas capacity is large. Somewhere in the pipe, the pointer display value of the pressure gauge will not drop in a short time, even for more than ten days. Therefore, this method is unreliable for finding leaks.

Reliable detection method:

1. First check whether the exposed pipeline leaks; (the exposed pipeline can be checked for leakage with soap bubbles)

2. If there are no leaks in the exposed pipe, it is time to weld in a pressure gauge to check the internal pipe condition.

3. Weld a pressure gauge on the low-pressure pipe (Φ6mm, also called the intake pipe) and the high-pressure gas-out pipe (Φ5mm) near the compressor;

4. Cut off the capillary at a distance of 5mm from the filter, and plug the ends of the cut capillary with solder;

5. Add dry air from the process tube of the compressor to a pressure of 0.68MPa, and then block the process tube to maintain this internal air pressure;

6. Wait for the temperature of all welding places to be equal to the ambient temperature (for about 1 hour), and then use a marker pen to mark the position of the gauge needle on the transparent glass cover of the pressure gauge;

7. Keep observing for 2-3 days (the condition is that the ambient temperature does not change much, otherwise it will affect the value of the air pressure inside the pipeline);

8. During the observation process, if the pointer value of one of the pressure gauges decreases, please mark it on the corresponding dial transparent cover;

9. After continuing to observe for 2-3 days, the pressure drops even more, which proves the fact that the pipeline connected to the pressure gauge has leaked.

Analyze separately according to the leakage of the condenser and the leakage of the evaporator:

a) If the value of the pressure gauge in the evaporator part drops, it needs to be checked again in sections.

Check the evaporator section by section:

Pry off the back plate, separate the upper and lower evaporators, insert the pressure gauge, and continue to increase the air pressure test until the specific part of the evaporator section with loopholes is traced.

b) If it is the pressure drop of the condenser part, the cause should be determined according to its structure.

If it is a condenser with a back-mounted structure, the most likely cause is the perforation of the dew pipe on the door frame.

If it is a built-in condenser, it is necessary to further test the local pressure value changes in sections, and insert a new pressure gauge into the pipeline to achieve it.

The Difference Between Static Cooling And Dynamic Cooling System

Compare with static cooling system, dynamic cooling system is better to continuously circulate the cold air around inside the refrigeration compartment...

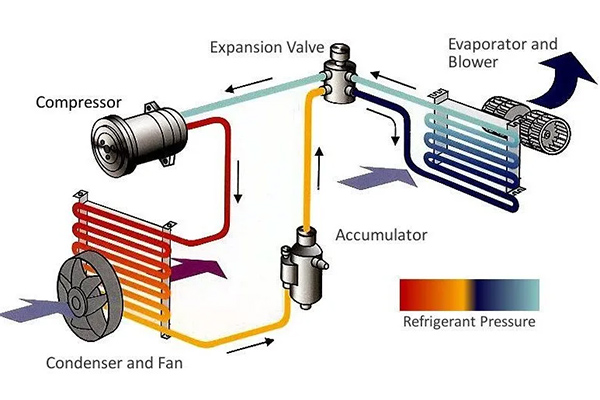

Working Principle Of Refrigeration System – How Does It Work?

Refrigerators are extensively used for residential and commercial application to help store and keep food fresh for longer, and prevent spoilage ...

7 Ways to Remove Ice from a frozen Freezer (the Last Method Is Unexpected)

Solutions to removing ice from a frozen freezer including cleaning the drain hole, changing the door seal, manual removing the ices ...

Products & Solutions For Refrigerators And Freezers

Retro-Style Glass Door Display Fridges For Beverage & Beer Promotion

Glass door display fridges can bring you something a little different, as they are designed with an aesthetic appearance and inspired by the retro trend ...

Custom Branded Fridges For Budweiser Beer Promotion

Budweiser is a famous American brand of beer, which was first founded in 1876 by Anheuser-Busch. Today, Budweiser has its business with a significant ...

Custom-Made & Branded Solutions For Refrigerators & Freezers

Nenwell has extensive experience in customizing & branding a variety of stunning and functional refrigerators & freezers for different businesses...

Post time: Oct-15-2023 Views: