In the previous issue, we shared the types of cake display cabinets. This issue focuses on temperature controllers and the cost-effective selection of cake cabinets. As a core component of refrigeration equipment, temperature controllers are used in refrigerated cake cabinets, quick-freezing freezers, air conditioners, and beverage freezers, among others.

What is the history of temperature controllers?

At the end of the 19th century, thermodynamics research began to explore how to automatically control temperature. At that time, the earliest temperature control methods involved regulating the temperature of air and water through hot air heaters and hot water pipes. At the beginning of the 20th century, with the development of electrical technology, automatic control technology was realized. In 1912, American Allen Bradley invented the first electronic-based temperature controller. Later, with industrialization, more and more manufacturers around the world began to research and develop temperature controllers, spurring the development of the temperature controller industry.

Today, modern temperature controllers adopt digital circuit technology and microprocessor technology, becoming increasingly intelligent, precise, and stable. They feature automatic temperature adjustment, real-time alarm, and remote monitoring functions, and are widely used in various industries, especially the refrigeration industry.

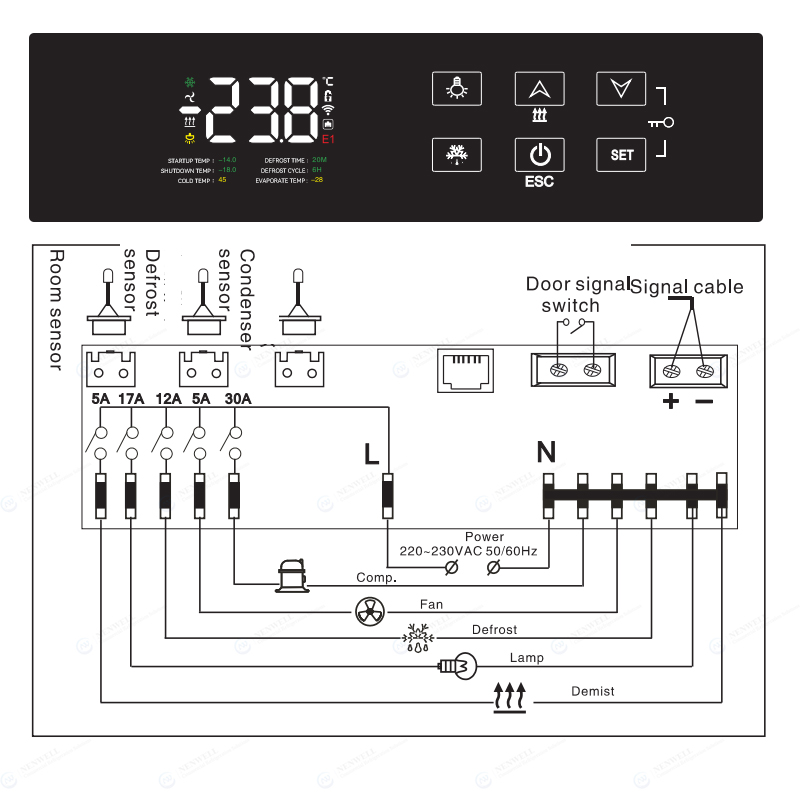

The mature development of IoT technology has given rise to IoT refrigeration and freezing intelligent controllers. These controllers control components such as compressors, fans, lighting equipment, and motors through air-cooled system microcomputer controllers and relay output current and voltage, and regulate temperature to achieve defrosting and refrigeration effects.

The basic principle of defrosting is to input an appropriate temperature through a sensor. When the temperature rises slightly (similar to the heating mode of air conditioners or the heating wires in refrigerators), the frost layer absorbs heat and melts from solid ice into liquid water, which then flows away or evaporates.

How to remotely control the temperature controller of freezing equipment?

For large shopping malls or supermarkets, there are dozens of beverage refrigeration upright cabinets and many cake cabinets in the baking area, making maintenance difficult if done one by one. IoT technology enables centralized remote management of multiple devices. The background allows monitoring of equipment operating data, working status, and temperature parameter settings, greatly improving maintenance efficiency. Remote control is available on computer and mobile terminals, requiring the installation of a customized APP.

(1) Data security detection

If the temperature of an upright cabinet or cake cabinet is abnormal, the probe inside the temperature controller will detect the abnormal data and remind the user via a remote APP or SMS, effectively ensuring safety with comprehensive early warning functions.

(2) User-friendly functional area

Remote control allows one-click startup, lighting and temperature control, real-time sharing of remote data, and personalized data analysis, recording, and display functions to meet different user needs.

Is the temperature control of cake refrigeration cabinets the same as that of cola beverage freezers?

Temperature controllers can be adapted to all devices that require temperature control, including cake refrigeration cabinets and cola beverage upright cabinets. The principles have been analyzed in detail above, and the differences are as follows:

1.Different appearance styles

Depending on the size of the refrigeration equipment and display type (mechanical, touch screen), there are many models of temperature controllers, such as strip-shaped, square, small embedded, multi-button, touch-controlled, and mechanical types. The specific selection depends on the equipment used. For example, small commercial beverage upright cabinets use relatively small-sized temperature controllers, while large island-style cake cabinets can use multi-button or touch-controlled controllers.

2.Different power consumption

Due to different usage scenarios, power consumption also varies. Generally speaking, temperature controllers with more advanced digital display panels and richer functions consume more power, and vice versa.

3.Different prices

Different models have different prices, and the right model should be chosen according to needs. A higher price does not necessarily mean a better product; instead, cost-effectiveness should be considered. Customized products are generally more expensive and suitable for large-volume export trade orders.

In 2025, AI and IoT are developing rapidly, which is of great significance for promoting the development of IoT temperature controllers for display cabinets. To survive, major enterprises are innovating and improving user experience. That’s all for this issue. Thank you for reading. In the next issue, we will share the global rankings of commercial intelligent upright cabinets and cake cabinets.

Post time: Jul-25-2025 Views: