In a bustling shopping mall, the Italian ice cream freezer showcases ice creams of different flavors to meet the needs of various customers. However, in China, the variety is not as rich. With the development of global trade, unique ice cream cabinets have been introduced into the domestic market, and their main features are as follows.

1.A large number of inner slots

There are 10 – 15 large – capacity stainless – steel inner slots, which can hold different types of ice creams. These slots are made of 4mm – thick material, which will not deform after long – term use. The edges are polished, making each inner slot shiny. It feels comfortable to hold. In particular, the size is precisely designed, perfectly fitting each position, and it is not easy to shake in a moving environment. The depth is also calculated accurately according to the total capacity of each model, and users can choose according to their actual usage needs.

2.Appearance and shape design

Typically, Italian ice cream cabinets adopt a right – angled glass panel design. The glass thickness is about 4mm – 6mm, using high – strength tempered vacuum glass, which can effectively isolate cold air and reduce the loss of cold air inside the cabinet, ensuring excellent heat – preservation performance. Of course, in terms of shape, there are also design styles such as arc – shaped and polygon – shaped. You can refer to the actual product pictures for comparison. Compared with traditional designs, it has a unique style. For those with high customization difficulty, the price will be much higher.

In terms of structure, the ice cream cabinet is assembled through a combination of high – strength glue and screw – fixing methods. For example, each piece of glass is fixed to the load – bearing frame with glue or by screws. The sealing performance of the glue – fixing method is relatively good. If the screw – fixing method is used, a sealing gasket (made of rubber) is required.

3.Design details of the glass cabinet door

The cabinet door is commonly a sliding – type. According to market data analysis, the push – open door type is more commonly used. The main advantage of the pull – door type is that the opening area is large, which is convenient for placing and taking items. However, the disadvantage is that the large opening area will lead to more cold air loss and hot air inflow, which has an impact on the ice cream, such as the rapid formation of water droplets and frost inside the cabinet. The push – open door design uses a track method. The advantages are that it does not occupy space and the door can be opened and closed flexibly. The disadvantage is that only one door can be opened, either on the left or the right, and it is opened by pushing, which may cause a little obstruction for putting items on or taking them off the shelves. However, this is an advantage in terms of heat preservation, reducing the inflow of hot air.

It should be noted that the thickness of the cabinet door design, especially the thickness of the track, should be at least 4mm, otherwise it will deform after long – term use. The material is required to be 304 stainless steel, which is not easy to rust and is corrosion – resistant. These details are important evaluation indicators.

More information:

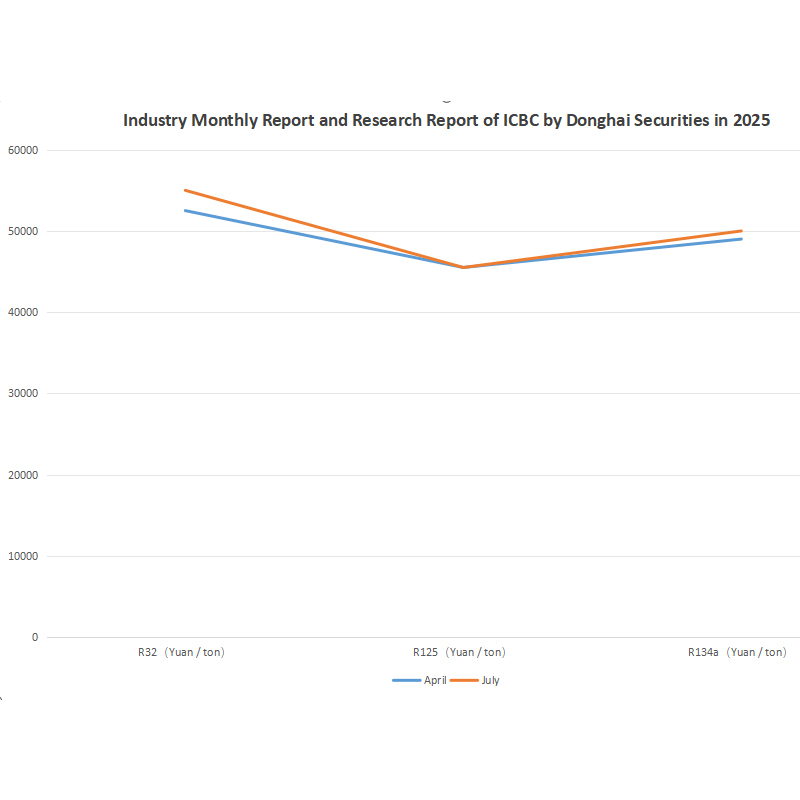

The fluorine – chemical industry monthly report and research report recently released by Donghai Securities in China shows that as of July 31, 2025, the prices of the third – generation refrigerants R32, R125, and R134a were 55,000 yuan/ton, 45,500 yuan/ton, and 50,000 yuan/ton respectively, an increase of 4.76%, 0%, and 2.04% respectively compared with the end of April; the price of R22 was 35,000 yuan/ton, the same as last month, an increase of 14.75% compared with the same period last year, with a price difference of 26,842 yuan/ton, a decrease of 0.55% compared with the end of last month. The prices of fluoropolymers have declined, and there are corresponding prices for various categories such as PTFE, PVDF, and HFP.

Nenwell stated that in 2025, the quota for the second – generation refrigerants will be cut, the quota for the third – generation refrigerants will remain at the baseline, the supply – demand situation will tighten, the refrigerant prices will rise steadily, the performance of related enterprises is expected to increase, and the industry is expected to maintain a high – prosperity level. The profitability of refrigerator and freezer enterprises may increase significantly.

In 2025, there is a growth trend for dual – system refrigerators. Industry data shows that the market share of dual – system refrigerators increased by 15% year – on – year in 2024. It is expected that this trend will accelerate further in 2025. Especially in first – tier cities, the penetration rate of dual – system refrigerators has exceeded 30%, making them the first choice for high – end families.

Post time: Aug-18-2025 Views: