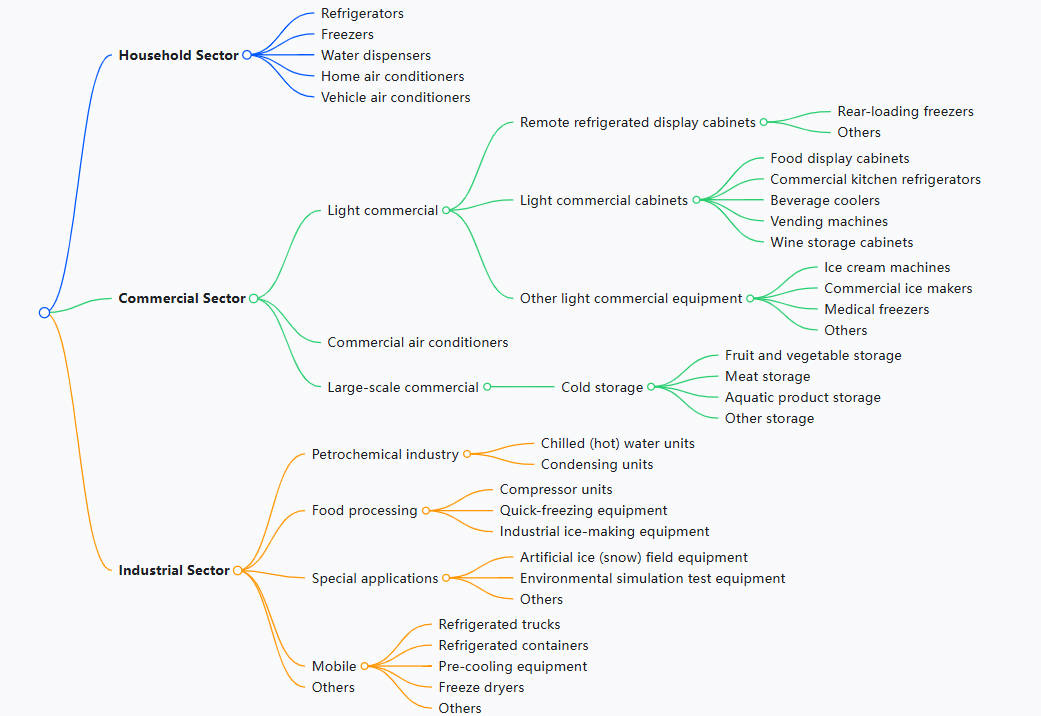

Modern refrigeration equipment is essential for food preservation, yet refrigerants such as R134a, R290, R404a, R600a, and R507 differ significantly in application. R290 is commonly used in refrigerated beverage cabinets, while R143a is frequently employed in small beer cabinets. R600a is typically reserved for specialised freezing equipment.

Refrigerants are the lifeblood of refrigeration systems, enabling fridges to absorb heat and maintain cool internal temperatures. However, not all refrigerants are created equal—their chemical composition, environmental impact, safety profiles, and performance vary significantly. For consumers, technicians, and industry professionals in Europe and North America, understanding these differences is critical, especially amid strict regulatory pushes to reduce greenhouse gas emissions and protect the ozone layer.

Core Evaluation Criteria for Refrigerants

Before diving into individual types, it’s essential to define the metrics that matter most for refrigerator applications. These criteria are universally recognized in the HVAC/R (Heating, Ventilation, Air Conditioning, Refrigeration) industry and shape regulatory decisions globally:

- ODP (Ozone Depletion Potential): A measure of how much a substance damages the ozone layer. The benchmark is R11 (a now-banned refrigerant), with an ODP of 1. A rating of 0 means the refrigerant has no ozone-depleting effects.

- GWP (Global Warming Potential): A measure of a substance’s contribution to climate change over 100 years, compared to carbon dioxide (CO₂, GWP = 1). Lower GWP values are prioritized under regulations like the EU’s F-Gas Regulation and the U.S. EPA’s SNAP (Significant New Alternatives Policy).

- ASHRAE Safety Classification: A standard (ASHRAE 34-2022) that rates refrigerants by flammability (Class 1: non-flammable; Class 2L: slightly flammable; Class 2: flammable; Class 3: highly flammable) and toxicity (Class A: low toxicity; Class B: high toxicity). Most refrigerator refrigerants fall into Class A.

- Thermodynamic Performance: Includes cooling efficiency (COP, or Coefficient of Performance, where higher = more efficient), operating pressure (must match the fridge’s compressor design), and temperature range (suitable for medium-temperature fridges or low-temperature freezers).

- Compatibility: Works with the fridge’s compressor lubricants (e.g., mineral oil, POE oil) and materials (e.g., seals, hoses) to avoid system damage.

Individual Refrigerant Analysis

Each refrigerant has unique strengths and limitations, making it suitable for specific use cases—from household fridges to commercial freezers. Below is a detailed breakdown of each type.

1. R134a (Tetrafluoroethane)

Chemical Type: Pure hydrofluorocarbon (HFC)

Key Specs:

- ODP: 0 (ozone-safe)

- GWP: 1,430 (per IPCC Sixth Assessment Report, 100-year horizon)

- ASHRAE Safety Class: A1 (non-flammable, low toxicity)

- Operating Pressure: Medium (compared to other refrigerants)

- Compatibility: Works with POE (polyol ester) or PAG (polyalkylene glycol) lubricants.

Performance & Applications:

R134a emerged in the 1990s as a replacement for R12 (a CFC with high ODP, now banned under the Montreal Protocol). It became a staple in household fridges, small beverage coolers, and portable refrigerators due to its non-flammable nature and easy integration into existing systems. Its cooling efficiency (COP) is moderate—sufficient for standard fridge temperatures (2–8°C for the fresh compartment, -18°C for freezers) but lower than natural refrigerants like R600a.

Regulatory & Environmental Status:

While R134a is ozone-safe, its high GWP has led to restrictions in Europe and North America. Under the EU’s F-Gas Regulation (EC No 517/2014), R134a’s use in new refrigeration equipment has been phased down since 2020, with further reductions planned. It remains common in older fridges but is being replaced by low-GWP alternatives in new models.

Challenges: High GWP limits long-term viability; lower efficiency than natural refrigerants.

2. R600a (Isobutane)

Chemical Type: Pure hydrocarbon (HC, a “natural refrigerant” derived from petroleum/gas)

Key Specs:

- ODP: 0 (ozone-safe)

- GWP: 3 (negligible climate impact—one of the lowest available)

- ASHRAE Safety Class: A3 (highly flammable, low toxicity)

- Operating Pressure: Low (requires compressors designed for low-pressure systems)

- Compatibility: Works with mineral oil or alkylbenzene (AB) lubricants (not POE/PAG).

Performance & Applications:

R600a is now the dominant refrigerant in modern household fridges in Europe and North America. Its high cooling efficiency (COP 5–10% higher than R134a) reduces energy consumption, aligning with EU Energy Label and U.S. ENERGY STAR® standards. Its low GWP also makes it fully compliant with strict emissions regulations.

Safety & Installation Considerations:

Flammability is R600a’s primary challenge. To mitigate risk, manufacturers limit its charge size in fridges (typically ≤150 grams) and use explosion-proof components (e.g., sealed compressors, non-sparking electrical parts). Technicians require specialized training to handle leaks, as concentrated R600a vapor is flammable.

Challenges: High flammability requires safety-focused design and handling; incompatible with POE/PAG oils.

3. R290 (Propane)

Chemical Type: Pure hydrocarbon (HC, natural refrigerant)

Key Specs:

- ODP: 0 (ozone-safe)

- GWP: 3 (same as R600a, ultra-low climate impact)

- ASHRAE Safety Class: A3 (highly flammable, low toxicity—slightly more flammable than R600a, with a lower ignition energy)

- Operating Pressure: Medium-low (higher than R600a, lower than R134a)

- Compatibility: Works with mineral oil or AB lubricants.

Performance & Applications:

R290 offers exceptional cooling efficiency—its COP is 10–15% higher than R134a, making it ideal for energy-efficient refrigeration. It is used in small to medium household fridges, mini-fridges, and some commercial display coolers (where charge sizes are limited). In regions like the EU, it is increasingly adopted as a direct replacement for R134a in new models.

Safety & Regulatory Status:

Like R600a, R290’s flammability requires strict safety measures: charge limits (≤150 grams for household fridges), leak detection systems, and non-combustible materials in the fridge’s interior. It is fully compliant with the EU F-Gas Regulation and U.S. EPA SNAP, with no phase-down plans due to its low GWP.

Challenges: Higher flammability than R600a; requires more rigorous safety testing during manufacturing.

4. R404a (Blend of R125, R134a, R143a)

Chemical Type: Near-azeotropic HFC blend (multiple HFCs mixed to mimic the properties of a single refrigerant)

Key Specs:

- ODP: 0 (ozone-safe)

- GWP: 3,922 (extremely high—one of the most climate-impacting refrigerants)

- ASHRAE Safety Class: A1 (non-flammable, low toxicity)

- Operating Pressure: High (optimized for low-temperature systems)

- Compatibility: Works with POE lubricants.

Performance & Applications:

R404a was once the gold standard for commercial refrigeration, including walk-in freezers, supermarket display cases, and industrial fridges that operate at -20°C to -40°C. Its high cooling capacity and stability at low temperatures made it ideal for these applications.

Regulatory & Environmental Status:

R404a’s ultra-high GWP has led to its near-total phase-out in Europe and North America. Under the EU F-Gas Regulation, its use in new equipment was banned in 2020, and its import/export is heavily restricted. In the U.S., the EPA has listed R404a as a “high-GWP substance” and requires replacement with low-GWP alternatives (e.g., R452A, R513A) in new systems. It remains in older commercial fridges but is being phased out through retrofits.

Challenges: Prohibitive GWP; poor energy efficiency compared to modern alternatives; contributes significantly to climate change.

5. R507 (Blend of R125 & R143a)

Chemical Type: Azeotropic HFC blend (mixes that boil/condense at a single temperature, like a pure refrigerant)

Key Specs:

- ODP: 0 (ozone-safe)

- GWP: 3,985 (nearly identical to R404a, ultra-high)

- ASHRAE Safety Class: A1 (non-flammable, low toxicity)

- Operating Pressure: High (slightly higher than R404a)

- Compatibility: Works with POE lubricants.

Performance & Applications:

R507 is a close cousin of R404a, designed for low-temperature commercial refrigeration (e.g., deep freezers, frozen food display cases) where consistent cooling at -30°C to -50°C is required. Its azeotropic nature means it does not separate into components during leaks, simplifying maintenance—an advantage over near-azeotropic blends like R404a.

Regulatory & Environmental Status:

Like R404a, R507’s high GWP has led to strict regulations. The EU F-Gas Regulation banned its use in new equipment in 2020, and the U.S. EPA has designated it as a “substance of concern” under SNAP. It is being replaced by low-GWP alternatives such as R448A (GWP = 1,387) and R449A (GWP = 1,397) in commercial applications.

Challenges: Extremely high GWP; no long-term viability under global emissions rules; limited to legacy systems.

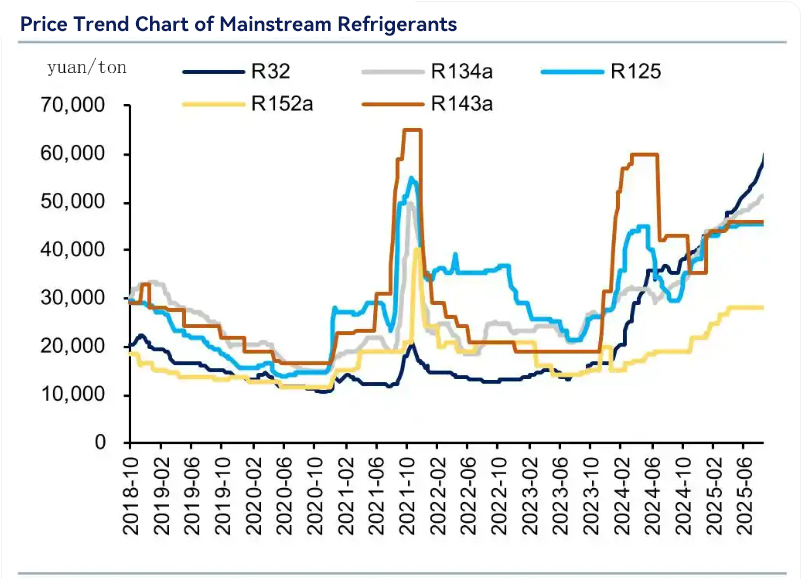

The price trends of different refrigerants vary. This is the trend chart as of June 2025:

Comparative Overview of Refrigerants

The table below summarizes the key differences between the five refrigerants, highlighting their suitability for specific use cases:

|

Refrigerant |

Type |

ODP |

GWP (100-yr) |

ASHRAE Class |

Operating Pressure |

Typical Application |

Environmental Compliance (EU/US) |

Primary Challenge |

|

R134a |

Pure HFC |

0 |

1,430 |

A1 |

Medium |

Older household fridges |

Phased down; limited in new gear |

High GWP; low efficiency |

|

R600a |

Pure HC |

0 |

3 |

A3 |

Low |

Modern household fridges |

Fully compliant; no phase-down |

High flammability |

|

R290 |

Pure HC |

0 |

3 |

A3 |

Medium-low |

Energy-efficient household fridges |

Fully compliant; no phase-down |

Higher flammability than R600a |

|

R404a |

HFC Blend |

0 |

3,922 |

A1 |

High |

Legacy commercial freezers |

Banned in new equipment |

Ultra-high GWP; climate impact |

|

R507 |

HFC Blend |

0 |

3,985 |

A1 |

High |

Legacy low-temp freezers |

Banned in new equipment |

Ultra-high GWP; limited future |

Regulatory Trends & Industry Shifts

The global refrigerant market is being driven by two overarching goals: eliminating ozone-depleting substances (achieved for most refrigerants) and reducing greenhouse gas emissions (the current focus). In Europe and North America, regulations are accelerating the shift to low-GWP options:

- EU F-Gas Regulation: Mandates a 79% reduction in HFC consumption by 2030 (compared to 2015 levels) and bans high-GWP refrigerants (GWP > 2,500) in new refrigeration equipment.

- U.S. EPA SNAP: Lists low-GWP refrigerants (e.g., R600a, R290, R452A) as “acceptable” for most applications and prohibits high-GWP options (e.g., R404a, R507) in new systems.

For consumers, this means:

- New household fridges will almost exclusively use R600a or R290 (due to their low GWP and high efficiency).

- Commercial refrigeration will shift to low-GWP blends (e.g., R448A, R454C) or natural refrigerants like CO₂ (R744) for large systems.

- Older fridges using R134a, R404a, or R507 will require proper disposal or retrofitting to comply with regulations.

Choosing the right refrigerant for a fridge depends on balancing four factors: environmental impact (ODP/GWP), safety (flammability/toxicity), performance (efficiency/pressure), and regulatory compliance. For most modern applications:

- R600a and R290 are the best choices for household fridges, offering ultra-low GWP and high efficiency (with safety measures to address flammability).

- R404a and R507 are obsolete for new systems, limited to legacy commercial equipment until retrofits or replacement.

- R134a is a transitional option, gradually being phased out in favor of natural refrigerants.

As regulations tighten and technology advances, the industry will continue to prioritize natural refrigerants and low-GWP blends—ensuring refrigeration systems are both effective and sustainable for the long term. For technicians and consumers, staying informed about these differences is key to making responsible, compliant decisions.

Sources: ASHRAE Handbook—Refrigeration (2021), IPCC Sixth Assessment Report (2022), EU F-Gas Regulation (EC No 517/2014), U.S. EPA SNAP Program (2023).

Post time: Oct-23-2025 Views: