The accessories of commercial beverage upright cabinets are divided into four categories: door accessories, electrical components, compressors, and plastic parts. Each category contains more detailed accessory parameters, and they are also important components of refrigerated upright cabinets. Through assembly, a complete device can be formed.

I. Door Accessories

Door accessories include eight categories of parts: door body, door frame, door handle, door seal strip, door lock, hinge, glass, and vacuum interlayer strip. The door body mainly consists of door panels and door liners of different materials.

- Door Panel: Usually refers to the outer layer of the door, which is the “surface layer” of the door, directly determining the appearance, texture, and some protective properties of the door. For example, the outer solid wood board of a solid wood door and the decorative panel of a composite door both belong to door panels. Its main function is to form the external shape of the door, and at the same time, it plays a certain role in isolation, aesthetics, and basic protection.

- Door Liner: Mostly exists in composite – structured doors. It is the internal filling or support structure of the door, equivalent to the “skeleton” or “core” of the door. Its main functions are to enhance the stability, sound insulation, and heat preservation of the door. Common door liner materials include honeycomb paper, foam, solid wood strips, and keel frames. For instance, the steel frame structure inside an anti – theft door and the heat – insulating filling layer in a heat – preserving door can be regarded as part of the door liner.

In simple terms, the door panel is the “face” of the door, and the door liner is the “lining” of the door. The two cooperate to form the complete function of the door body.

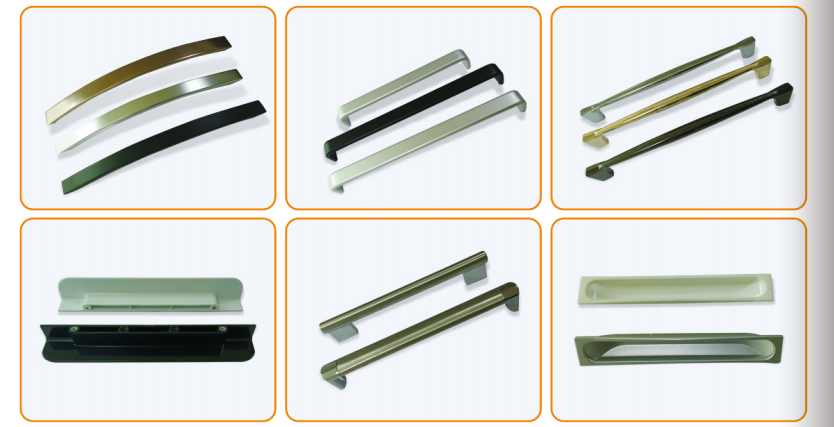

3. Door Handle: Generally, it is divided into handles of different materials such as metal and plastic. From the installation method, it can be divided into external installation and in – built structures, which are convenient for users to open and close the door.

4. Door Seal Strip: A sealing component installed on the edge of the door body of home appliances such as refrigerators, freezers, and beverage upright cabinets. Its main function is to fill the gap between the door and the cabinet. It is usually made of elastic materials such as rubber or silicone, with good flexibility and sealing performance. When the home appliance door is closed, the door seal strip will be squeezed and deformed, closely adhering to the cabinet, thus preventing the leakage of internal cold air (such as in a refrigerator) and at the same time preventing external air, dust, and moisture from entering. This not only ensures the working efficiency of the home appliance but also helps with energy conservation. In addition, some seal strips may be designed with magnetic materials (such as the door seal strip of an upright cabinet), using magnetic force to enhance the adsorption force between the door and the cabinet, further improving the sealing effect.

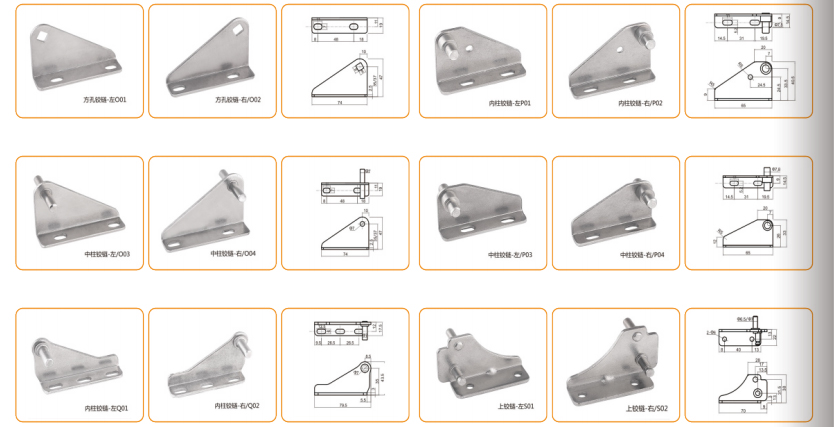

5. Door Hinge: A mechanical device that connects the door and the door frame. Its main function is to enable the door to rotate and open and close, and it also bears the weight of the door, ensuring that the door is stable and smooth during the opening and closing process. Its basic structure usually includes two movable blades (fixed on the door and the door frame respectively) and an intermediate shaft core, and the shaft core provides a pivot for rotation. According to different usage scenarios, there are various types of door hinges, such as the common hinge – type hinge (mostly used for indoor wooden doors), spring hinge (which can close the door automatically), and hydraulic buffer hinge (which reduces the noise and impact of closing the door). The materials are mostly metals (such as steel and copper) to ensure strength and durability.

6. Door Glass: If it is flat glass, there are types such as ordinary tempered glass, coated colored crystal glass, and Low – e glass, and there are also customized special – shaped glasses. It mainly plays the role of transmitting light and lighting, and at the same time has certain decorative and safety properties.

7. Vacuum Interlayer Strip: A material or component with a special structure. Its core design is to form a vacuum interlayer between two base materials. Its main function is to use the characteristics that a vacuum environment hardly conducts heat and sound, thus achieving good heat insulation, heat preservation, or sound insulation effects, and it is used for the heat preservation of upright cabinets.

II. Electrical Components

- Digital Temperature Display: An electronic device that can convert temperature signals into digital displays. It is mainly composed of a temperature sensor, a signal processing circuit, an A/D converter, a display unit, and a control chip. It can provide intuitive readings and has a fast response speed.

- NTC Probe, Sensing Wire, Connector: These three are used for the detection of temperature signals, the transmission of circuit signals, and the terminals for fixing the sensing wire and the probe.

- Heating Wire: A metal wire that converts electrical energy into heat energy after being energized. It generates heat by using the resistance characteristics of the metal and can be used in scenarios such as defrosting of upright cabinets.

- Terminal Block: A device used for circuit connection, which is used for the reliable connection between wires and electrical components. Its structure includes an insulating base and metal conductive terminals. The metal terminals are fixed by screws, buckles, etc., and the base insulates and separates different circuits to prevent short – circuits.

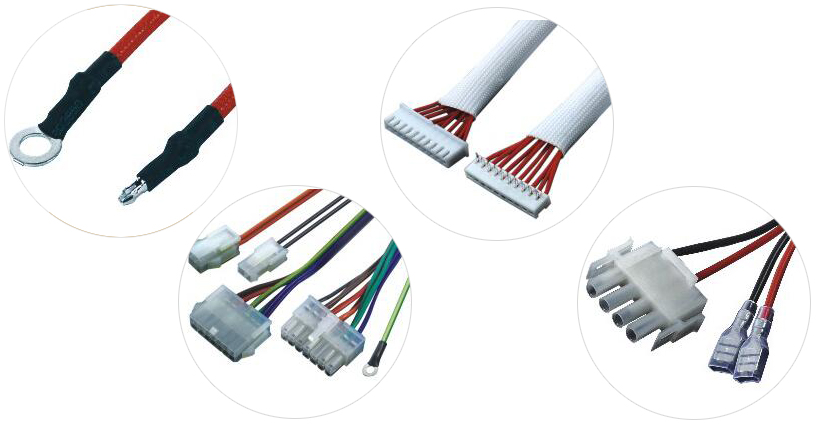

- Wires, Wire Harnesses, Plugs: Wires are an important bridge for transmitting electricity. A wire harness contains a large quantity of wires, not just a single line. A plug is the fixed head for connection.

- LED Light Strip: The LED light strip is an important component for the lighting of upright cabinets. It has different models and sizes. After being energized, through the controller switch circuit, it realizes the lighting of the device.

- Indicator Light (Signal Light): A signal light that displays the status of the device. For example, when the signal light is on, it indicates that there is power supply, and when the light is off, it indicates that there is no power supply. It is a component that represents a signal and is also an important accessory in the circuit.

- Switch: Switches include door lock switches, power switches, temperature switches, motor switches, and lighting switches, which control the operation and stop. They are mainly made of plastic and have an insulating function. They can be customized in different sizes, dimensions, and colors, etc.

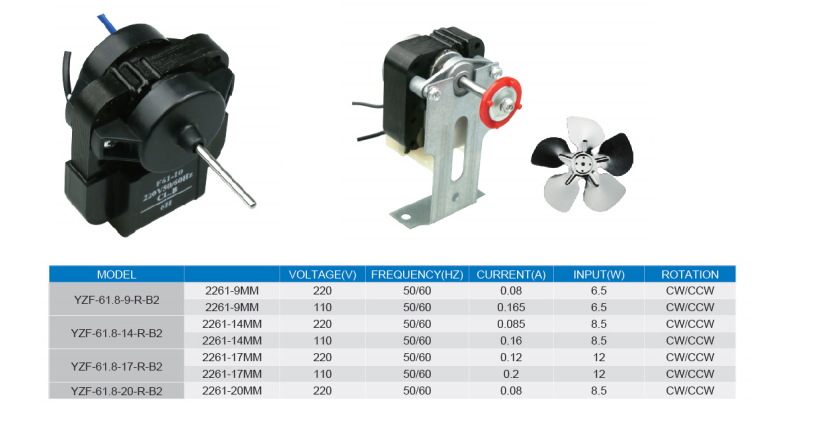

- Shaded – Pole Motor: The motor is also divided into the motor body and the asynchronous motor. The fan blade and the bracket are its key components, which are used in the heat – dissipation device of the upright cabinet.

- Fans: Fans are divided into external rotor shaft fans, cross – flow fans, and hot air blowers:

- External Rotor Shaft Fan: The core structure is that the motor rotor is coaxially connected to the fan impeller, and the impeller directly rotates with the rotor to push the air flow. It is characterized by a compact structure and a relatively high rotation speed, suitable for scenarios with limited space, such as the heat – dissipation of small – sized equipment and local ventilation. The air flow direction is mostly axial or radial.

- Cross – Flow Fan: The impeller is in the shape of a long cylinder. Air enters from one side of the impeller, passes through the inside of the impeller, and is sent out from the other side, forming an air flow that runs through the impeller. Its advantages are uniform air output, large air volume, and low air pressure. It is often used in air – conditioning indoor units, air curtains, and the cooling of instruments and meters, etc., where large – area uniform air supply is required.

- Hot Air Blower: Based on the blower, a heating element (such as an electric heating wire) is integrated. The air flow is heated and then discharged when it is transported by the fan. Its main function is to provide hot air and is applied in scenarios such as drying, heating, and industrial heating. The outlet air temperature can be controlled by adjusting the heating power and air volume.

- External Rotor Shaft Fan: The core structure is that the motor rotor is coaxially connected to the fan impeller, and the impeller directly rotates with the rotor to push the air flow. It is characterized by a compact structure and a relatively high rotation speed, suitable for scenarios with limited space, such as the heat – dissipation of small – sized equipment and local ventilation. The air flow direction is mostly axial or radial.

III. Compressor

The compressor is the “heart” of the refrigeration system. It can compress the refrigerant from low – pressure steam to high – pressure steam, drive the refrigerant to circulate in the system, and realize the transfer of heat. It is the most important accessory of the upright cabinet. In terms of types, it can be divided into fixed – frequency, variable – frequency, DC/vehicle – mounted. Each has its own advantages. Generally, variable – frequency compressors are more commonly selected. Vehicle – mounted compressors are mainly used in refrigeration equipment in cars.

IV. Plastic Parts

- Plastic Portioning Tray: It is mainly used for classifying and storing items. Utilizing the lightness and easy – to – clean characteristics of plastic materials, it is convenient for picking, placing, and organizing.

- Water Receiving Tray: It plays the role of collecting condensed water or leaked water, avoiding the direct dripping of water, which may cause damage to the cabinet or the ground due to moisture.

- Drain Pipe: It cooperates with the water receiving tray to guide the collected water to a designated position for discharge, keeping the interior dry.

- Air Pipe: It is mostly used for functions related to gas circulation, such as assisting in adjusting the air pressure in the cabinet or transporting specific gases. The plastic material is suitable for the needs of such pipelines.

- Fan Guard: It covers the outside of the fan, not only protecting the fan components from external collisions, but also guiding the direction of the air flow and preventing foreign objects from being be involved in the fan.

- Side Frame Strip: It mainly plays a role in structural support and decoration, strengthening the side structure of the cabinet and improving the overall aesthetics.

- Light Box Film: Usually, it is a plastic film with good light – transmission. It covers the outside of the light box, protects the internal lamps, and at the same time makes the light evenly penetrate, used for lighting or displaying information.

These components cooperate through their respective functions, enabling the upright cabinet to achieve coordinated operation in aspects such as storage, humidity control, ventilation, and lighting.

The above are the components of commercial beverage upright cabinet accessories. There are also components such as defrosting timers and heaters in the defrosting part. When choosing a branded upright cabinet, it is necessary to check whether each structure meets the standards. Generally, the higher the price, the better the craftsmanship. Many manufacturers produce, manufacture, and assemble according to this streamlined process. In fact, technology and cost are crucial.

Post time: Jul-29-2025 Views: