In the system of commercial refrigeration equipment, the condenser is one of the core refrigeration components, determining the refrigeration efficiency and equipment stability. Its main function is refrigeration, and the principle is as follows: it converts the high-temperature and high-pressure refrigerant vapor discharged by the compressor into a medium-temperature and high-pressure liquid through heat exchange, laying the foundation for the subsequent absorption of heat and vaporization of the refrigerant in the evaporator to achieve cooling and refrigeration. Common types of condensers include fin-tube condensers, wire-tube condensers, and tube-sheet condensers.

For large supermarkets in Europe and America, the refrigeration effect, energy consumption level, and service life of all refrigeration equipment, from refrigerated cabinets and freezers to large cold storage, are directly related to the performance of the condensers. Once problems such as insufficient heat dissipation efficiency, scaling, or blockage occur in the condensers, it will not only lead to a decrease in the refrigeration capacity of the equipment and temperature fluctuations inside the cabinets, affecting the freshness preservation quality of food, but also increase the operating load of the compressor, significantly increase power consumption, and even shorten the overall service life of the equipment.

Condensers have a wide range of application scenarios and are mainly used in major refrigeration equipment such as tabletop freezers, ice cream cabinets, ice makers, vertical beverage refrigerated display cabinets in supermarkets, cake cabinets, beer cabinets, and household refrigerators, playing an important role in food freshness preservation and refrigeration.

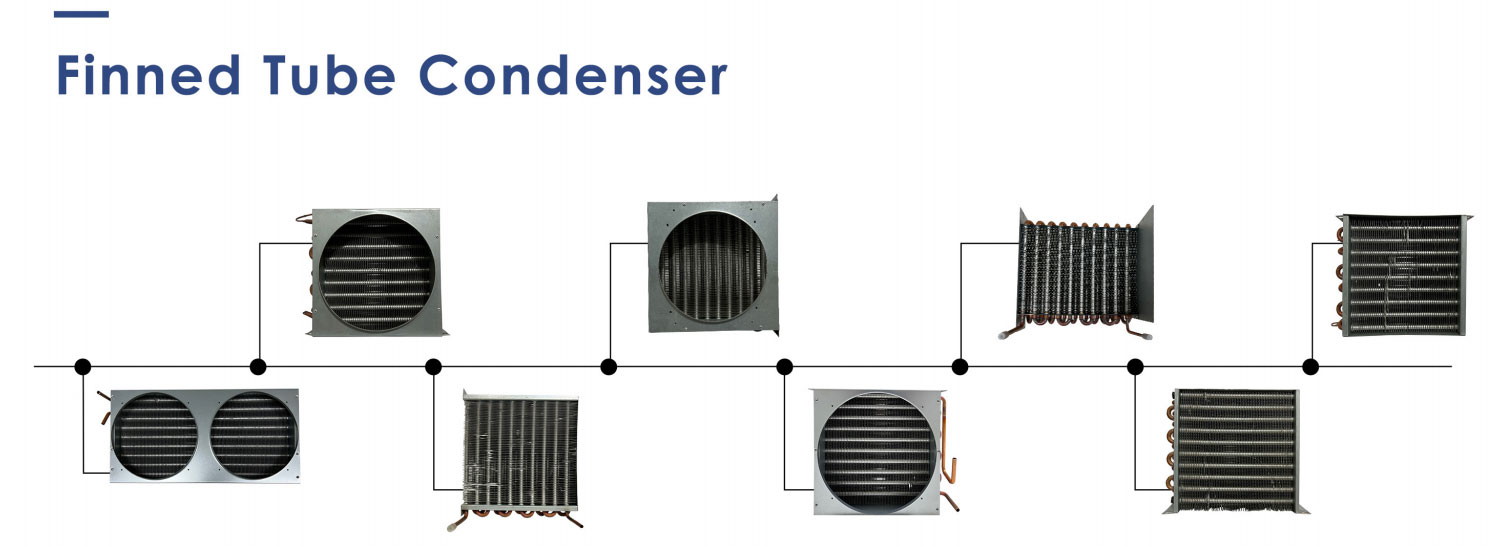

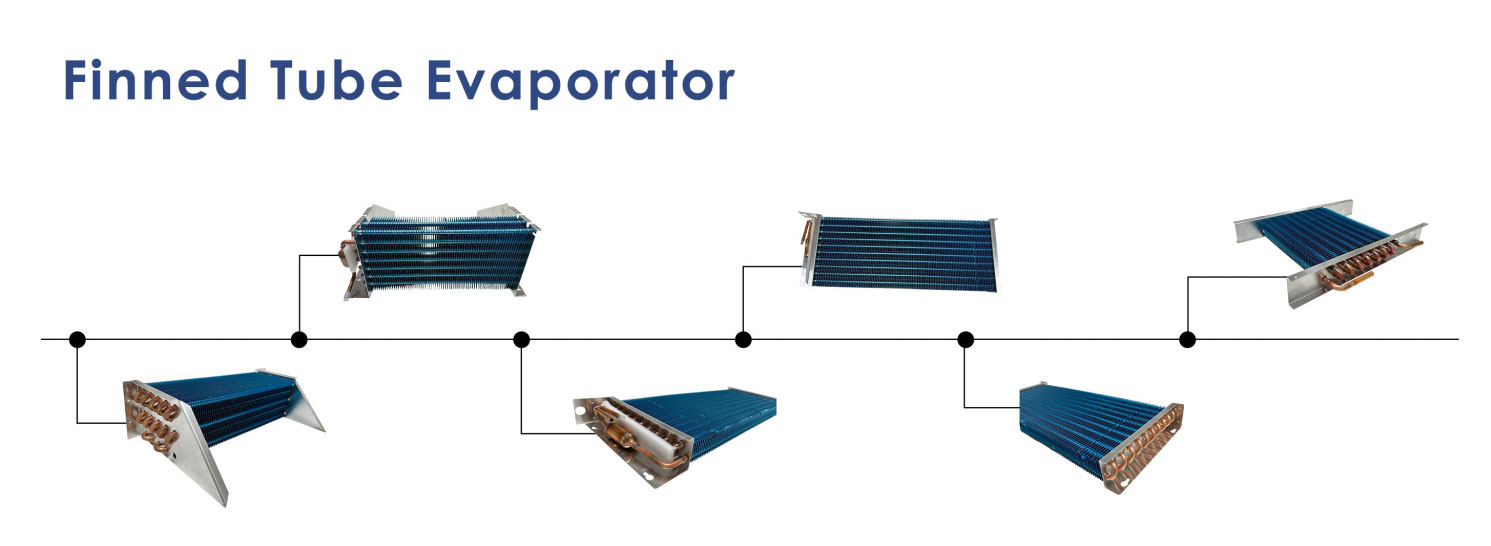

1. Fin-Tube Condensers: The Mainstream Choice for Efficient Heat Dissipation

The fin-tube condenser is one of the most widely used types of condensers. Its core structure consists of copper tubes (or aluminum tubes) and metal fins. By adding dense fins to the outer surface of the smooth metal tubes, the heat dissipation area is significantly increased, and the heat exchange efficiency is improved.

In terms of structural features, the fin material is mostly aluminum, and some high-end equipment uses copper fins. Aluminum fins have become the mainstream due to their advantages of low cost and light weight. The connection methods between the fins and copper tubes mainly include the fin-pressing method, the fin-wrapping method, and the fin-rolling method. Among them, the fin-rolling method is widely used in medium and high-end supermarket refrigeration equipment because the fins are closely combined with the copper tubes, resulting in low thermal resistance and higher heat dissipation efficiency.

In addition, to meet the installation requirements of different refrigeration equipment, fin-tube condensers can also be divided into air-cooled and water-cooled types. The air-cooled type does not require an additional water circulation system and is flexible to install, making it suitable for supermarket refrigerated cabinets, small freezers, etc. The water-cooled type has higher heat dissipation efficiency but requires higher water quality and needs a supporting cooling tower. It is mostly used in the central refrigeration systems of large supermarkets or high-load refrigeration equipment.

In terms of application scenarios and maintenance, due to their high heat dissipation performance and flexible installation methods, fin-tube condensers are widely used in supermarket open refrigerated cabinets, vertical freezers, combined cold storage, and other equipment.

During daily maintenance, it is necessary to regularly clean the dust and debris on the surface of the fins to prevent the blockage of the fin gaps from affecting heat dissipation. For air-cooled condensers, it is also necessary to check the operating status of the fan motor to ensure normal fan speed. For water-cooled condensers, the pipes need to be regularly cleaned to prevent scale from reducing the heat exchange efficiency, and at the same time, pay attention to checking for any leakage at the water pipe interfaces.

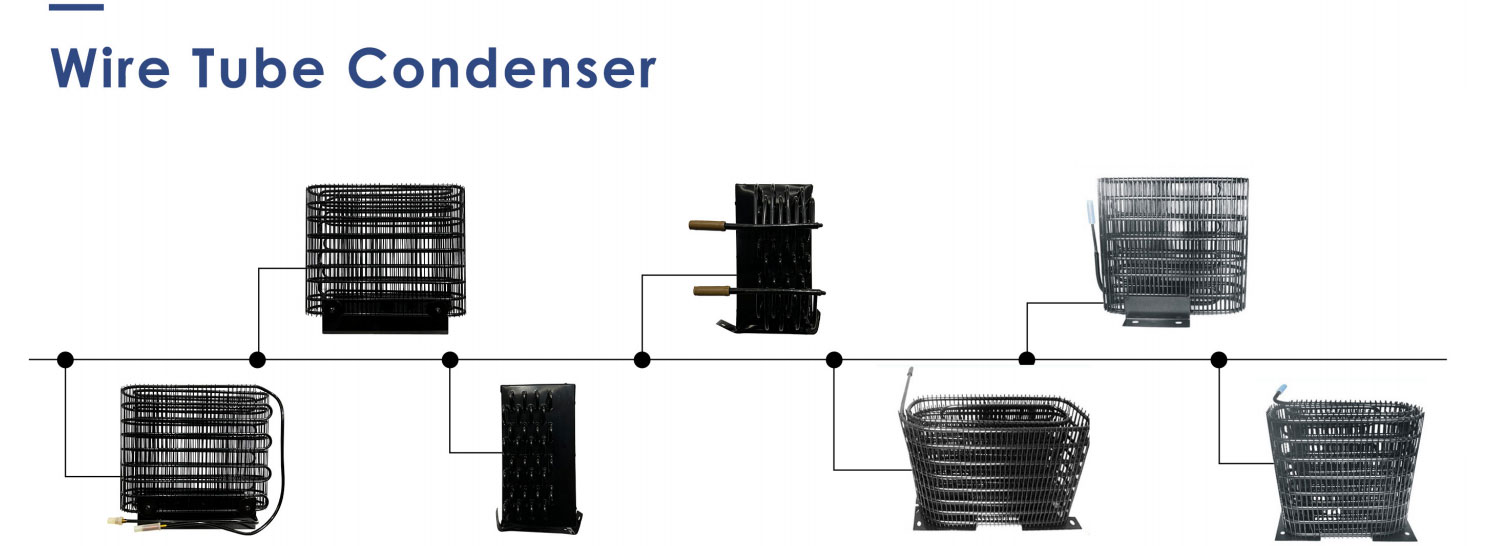

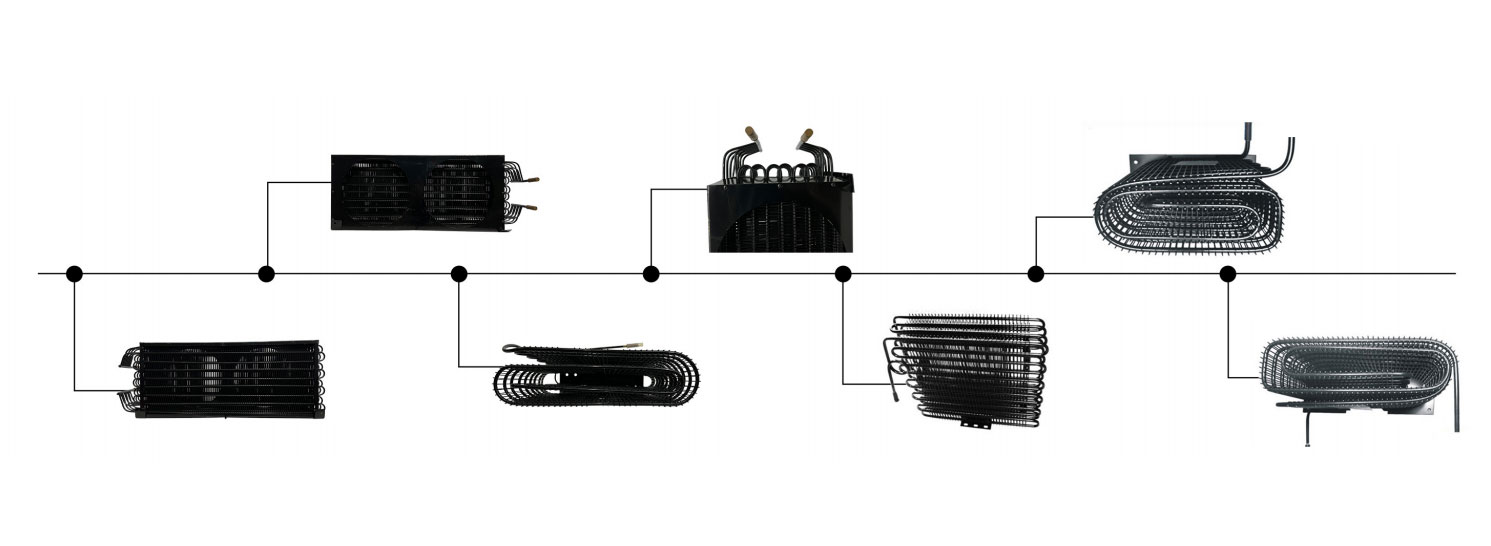

2. Wire-Tube Condensers: A Practical Choice with a Compact Structure

The wire-tube condenser, also known as the Bondi tube condenser, has the structural feature of arranging multiple thin copper tubes (usually Bondi tubes, i.e., galvanized steel tubes) in parallel and then spirally winding thin steel wires on the outer surface of the copper tubes to form a dense heat dissipation network. Compared with fin-tube condensers, its structure is more compact, the heat dissipation area per unit volume is larger, and the connection between the steel wires and copper tubes is firm, with stronger vibration resistance.

In terms of performance advantages, although its heat dissipation efficiency is slightly lower than that of fin-tube condensers, due to its compact structure and small space occupation, it is very suitable for installation in supermarket refrigeration equipment with limited space, such as small horizontal freezers and built-in refrigerated cabinets.

It should be noted that the surface of the wire-tube condenser is smooth, making it less prone to dust accumulation, and daily cleaning is relatively easy. It also has strong corrosion resistance and a long service life, especially suitable for the humid environment of supermarkets (such as refrigeration equipment near the aquatic product area and fresh produce area).

In terms of application scenarios, it is mainly used in small supermarket refrigeration equipment, such as tabletop refrigerated display cabinets, mini freezers, and some built-in fresh produce preservation cabinets. For maintenance, pay attention to the following: regularly wipe the surface dust with a soft cloth, and there is no need for frequent disassembly and cleaning; if the equipment is in a humid environment for a long time, check whether there is any rust on the surface of the condenser. Once rust is found, repair it with anti-rust paint in a timely manner to prevent the rust from spreading and affecting the heat dissipation performance; at the same time, avoid hard objects colliding with the steel wires and copper tubes of the condenser to prevent structural deformation from reducing the heat dissipation efficiency.

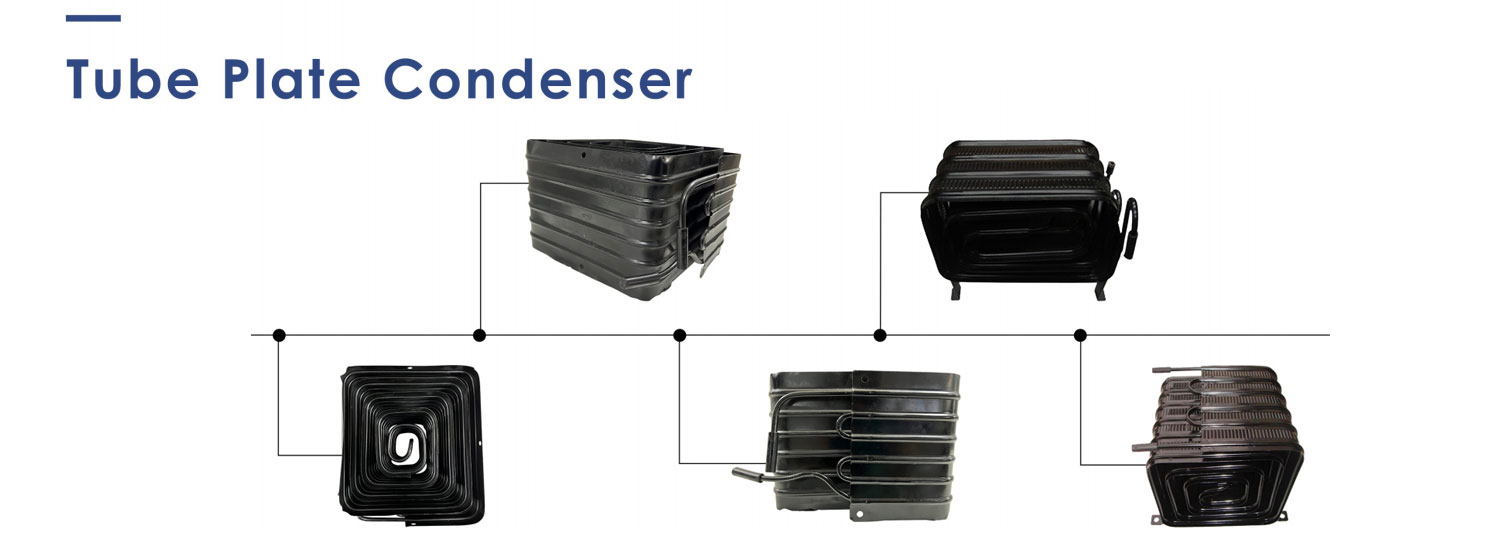

3. Tube-Sheet Condensers: A Reliable Choice for High-Strength Scenarios

The tube-sheet condenser is composed of a tube box, tube sheet, heat exchange tubes, and a shell. Its core structure is to fix both ends of multiple heat exchange tubes (usually seamless steel tubes or stainless steel tubes) on the tube sheet to form a tube bundle. The refrigerant in the tube box and the cooling medium (such as water or air) in the shell exchange heat through the tube wall. The tube-sheet condenser has high structural strength, excellent high-pressure and high-temperature resistance, and the connection between the heat exchange tubes and the tube sheet uses welding or expansion joint processes, with good sealing performance and is not prone to leakage problems.

In terms of structure and performance, it can be divided into shell-and-tube (water-cooled) and air-cooled shell-and-tube types. In the shell-and-tube tube-sheet condenser, cooling water is passed through the shell, and the refrigerant flows inside the heat exchange tubes, transferring heat to the cooling water through the tube wall. It has high heat dissipation efficiency and can withstand high pressure, making it suitable for high-pressure and high-load refrigeration equipment in supermarkets, such as large cold storage and central refrigeration systems. The air-cooled shell-and-tube tube-sheet condenser is equipped with a fan on the outside of the shell, and heat is carried away through air flow. It does not require a water circulation system and is more convenient to install, but its heat dissipation efficiency is slightly lower than that of the shell-and-tube type, suitable for scenarios with high pressure requirements but limited space.

With its characteristics of high strength and high sealing performance, the tube-sheet condenser is mainly used in large supermarket refrigeration equipment, such as ten-thousand-ton cold storage, central refrigeration units, and low-temperature freezers for storing meat and seafood.

During maintenance, it is necessary to regularly check the water quality of the cooling water to prevent scale and impurities from depositing inside the heat exchange tubes. Chemical cleaning or mechanical cleaning methods can be used to remove the dirt inside the tubes. At the same time, check whether there is any leakage at the connection between the tube sheet and the heat exchange tubes. If leakage is found, repair it by welding or replace the heat exchange tubes in a timely manner. For air-cooled shell-and-tube tube-sheet condensers, regularly clean the dust on the outside of the shell and check the operating status of the fan to ensure normal heat dissipation.

4. Tube-Sheet Evaporators: Key Components at the Refrigeration End

In many refrigeration equipment, the tube-sheet evaporator is the terminal component for achieving cooling and refrigeration. Its function is the opposite of that of the condenser. It mainly absorbs heat and vaporizes the low-temperature and low-pressure refrigerant liquid after throttling and pressure reduction inside the evaporator, absorbing the heat of the surrounding environment, thereby reducing the temperature of the refrigerated or frozen space. Its structure is similar to that of the tube-sheet condenser, consisting of a tube sheet, heat exchange tubes, and a shell, but the working medium and the direction of heat transfer are opposite.

In terms of structure and performance, according to the flow mode of the refrigerant, it can be divided into flooded type and dry type. In the flooded tube-sheet evaporator, the shell is filled with refrigerant liquid, and the heat exchange tubes are immersed in the liquid, exchanging heat with the cooled medium (such as air, water) through the tube wall. It has high heat exchange efficiency and is suitable for large supermarket cold storage, water chillers, and other equipment. In the dry tube-sheet evaporator, the refrigerant flows inside the heat exchange tubes, and the cooled medium flows inside the shell. It has a simple structure and is easy to maintain, suitable for small supermarket refrigerated cabinets, frozen display cabinets, and other equipment.

In terms of materials, copper or stainless steel is mostly used. Copper heat exchange tubes have good thermal conductivity, and stainless steel heat exchange tubes have strong corrosion resistance. The appropriate material can be selected according to the application scenarios of the equipment.

In terms of application scenarios, it is widely used in various refrigeration equipment, such as open refrigerated cabinets, vertical freezers, combined cold storage, water chillers, etc.

In terms of maintenance, check the frosting condition of the evaporator. If the frost is too thick, it will obstruct heat exchange and reduce the refrigeration efficiency. Defrosting should be carried out in a timely manner (electrical heating defrosting, hot gas defrosting, etc. can be used).

For flooded tube-sheet evaporators, control the refrigerant charging amount to avoid compressor liquid slugging caused by excessive charging. For dry tube-sheet evaporators, check whether there is any blockage in the heat exchange tubes. If blockage is found, high-pressure gas or chemical cleaning agents can be used for dredging. Do not overlook checking the sealing performance of the evaporator to prevent refrigerant leakage from affecting the refrigeration effect.

In commercial refrigeration equipment for supermarkets, different condensers and evaporators have their own unique structural features and application scenarios. It is necessary to reasonably select the corresponding models and sizes according to the type of equipment, space size, refrigeration load, and usage environment, and do a good job in daily maintenance to ensure the efficient and stable operation of the refrigeration equipment, provide reliable guarantee for food freshness preservation, and at the same time reduce energy consumption and operating costs.

Post time: Oct-11-2025 Views: