Anti-fog Heating Glass Door Improves Display Refrigerators

Abstract:

Electric heated glass on display refrigerators’ doors:

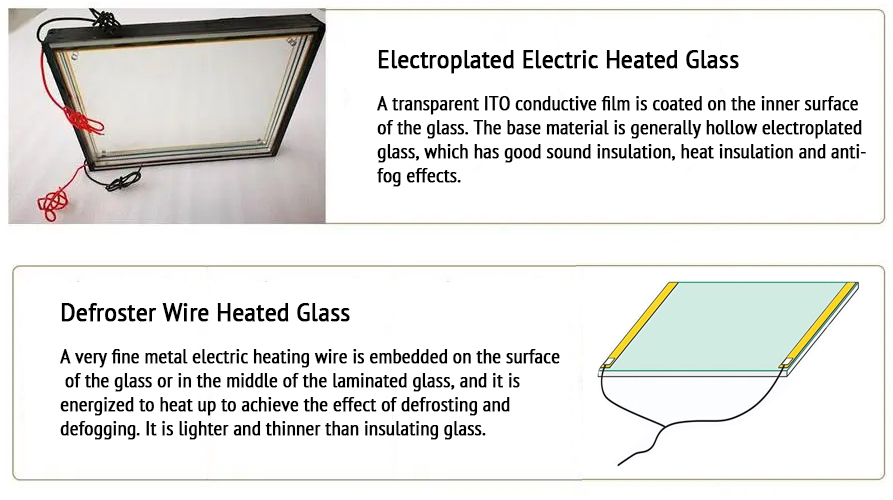

Type 1: Electroplated glass with heating layers

Type 2: Glass with defroster wires

In supermarkets, glass door display freezers showcase a wide variety of frozen products, allowing customers to easily observe and compare products from different brands, packaging, capacities, and qualities. Meanwhile, in convenience stores, each shelf of the glass door beverage fridges is filled with colorful beverages, enabling customers to instantly distinguish their brands, types, colors, textures, and capacities.

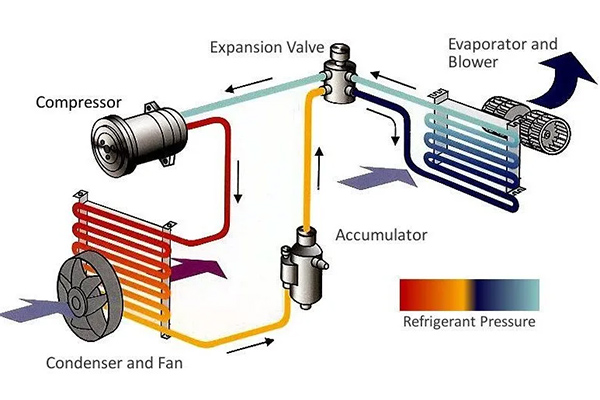

These glass display refrigerators are equipped with efficient refrigeration systems, capable of precisely maintaining the temperature inside the refrigerator much lower than room temperature. Display freezers maintain temperatures below -18 degrees Celsius, while refrigerated coolers maintain temperatures within the ideal range of 2-8 degrees Celsius. This temperature control not only ensures the long-term preservation of frozen and refrigerated products but also guarantees their hygiene and health, providing customers with a more enjoyable taste experience.

To simultaneously meet the requirements of low-temperature storage and display effectiveness, display coolers and freezers employ a design with glass doors. The transparent glass doors not only fully showcase the food inside the cabinet but also, coupled with interior lighting, make the food more visible, facilitating customer selection.

However, early glass door refrigerators faced a challenge during use: glass doors were prone to fogging up. Due to the higher humidity inside the refrigerator, water vapor would condense into water droplets on the cold glass, causing the originally transparent glass to become blurry, significantly obstructing customers' view. For display freezers, the situation was even more severe, as ice would sometimes form on the glass, turning the transparent glass door into frosted glass, completely obscuring the products inside.

To address this issue, modern glass door display refrigerators employ advanced anti-fogging technology to ensure that the glass doors remain clear and transparent, allowing customers to see the products inside clearly at all times. The introduction of this technology not only enhances the shopping experience for customers but also further underscores the importance of glass display refrigerators in supermarkets and convenience stores.

To solve the problem of fogging glass doors, engineers ingeniously applied a method of heating the glass. They found that when the temperature of the glass increases, water vapor does not condense on its surface, thus keeping the glass clean and transparent. Behind this innovative solution lies an important physical principle—Joule's Law. Joule's Law reveals the relationship between the heat generated by an electric current passing through a conductor and the current intensity, the resistance of the conductor, and the duration of current flow. Specifically, when an electric current passes through a conductor, the resistance of the conductor causes the current to be impeded and collide, thereby converting electrical energy into heat energy, resulting in an increase in the conductor's temperature.

Currently, there are two main approaches to achieve the effect of heating glass to prevent fogging:

The first is to use a heating wire to generate heat. By embedding heating wires inside the glass door, heat is generated when the wires are electrified, raising the temperature of the glass and preventing water vapor from condensing. This approach is characterized by its simplicity and effectiveness.

The second approach is to utilize electric heating coating technology. This technology involves coating the glass surface with a layer of conductive material. When electricity is applied, the coating quickly generates heat, causing the overall temperature of the glass to rise. This method not only achieves uniform heating but also maintains the transparency and aesthetics of the glass.

The heating wire heating solution actually borrows from the design concept of automobile rear-view mirrors. If you observe the rear-view mirror of a car, you will notice a row of dark lines on it, which are the heating wires. When the switch in the car's cabin is turned on, the heating wires are electrified and begin to heat up, effectively melting ice and snow adhering to the glass, ensuring a clear line of sight for the driver.

However, the situation with display refrigerators is quite different from that of car rear windows because customers usually stand in front of the refrigerator to view the products up close. If the heating wire lines are obvious, it not only easily catches the eye but also affects aesthetics. Therefore, the heating wires on display refrigerator glass doors are designed to be smaller to minimize interference with customers' sight. In most cases, unless customers look carefully, they will hardly notice the existence of heating wires on the glass doors of refrigerators.

However, due to the relatively fragile nature of small heating wires, both their production and their integration with glass pose certain challenges. Therefore, although this design is technically feasible, the use of small heating wires in display cabinets is not the mainstream choice. Currently, only a few brands in the market have adopted this fine design to meet the dual pursuit of aesthetics and practicality.

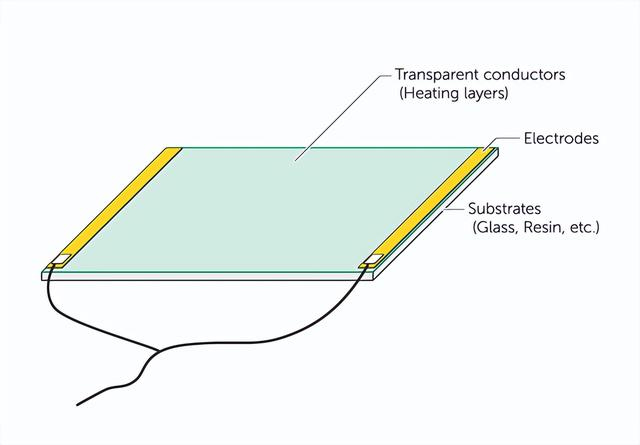

In practical applications, the heating coating solution is more commonly chosen for defogging glass doors of display refrigerators. This electrically heated glass is achieved by laying a layer of conductive film on the surface of flat glass. The conductive film is typically made of high-quality materials such as tin oxide or fluorine tin oxide, forming an extremely thin and uniform conductive film. When electricity is applied, this layer of conductive film rapidly generates heat, causing the entire glass surface to heat up evenly, effectively preventing water vapor condensation.

The design of the conductive coating is usually very sophisticated, involving multiple layers to optimize resistance heating effects. These layers include the conductive layer, the insulation layer, and the protective layer. The conductive layer is responsible for generating heat and conducting it to the glass, while the insulation layer effectively prevents heat from spreading to the back of the glass, ensuring that the heating effect is concentrated on the glass surface. The protective layer serves to protect the conductive layer from corrosion by the external environment, prolonging its service life.

When using electrically heated glass, if it is necessary to adjust the heating effect, it can be achieved by adjusting the duration and amount of electricity. This flexibility allows electrically heated glass to adapt to different environments and requirements, ensuring that the glass doors remain clear and transparent at all times.

In summary, the heating coating solution, with its efficient, uniform, and easily adjustable heating effect, plays an important role in defogging the glass doors of display refrigerators in supermarkets and convenience stores. With the continuous advancement of technology, this solution is expected to be more widely applied and optimized in the future.

The Difference Between Static Cooling And Dynamic Cooling System

Compare with static cooling system, dynamic cooling system is better to continuously circulate the cold air around inside the refrigeration compartment...

Working Principle Of Refrigeration System – How Does It Work?

Refrigerators are extensively used for residential and commercial application to help store and keep food fresh for longer, and prevent spoilage ...

7 Ways to Remove Ice from a frozen Freezer (the Last Method Is Unexpected)

Solutions to removing ice from a frozen freezer including cleaning the drain hole, changing the door seal, manual removing the ices ...

Products & Solutions For Refrigerators And Freezers

Retro-Style Glass Door Display Fridges For Beverage & Beer Promotion

Glass door display fridges can bring you something a little different, as they are designed with an aesthetic appearance and inspired by the retro trend ...

Custom Branded Fridges For Budweiser Beer Promotion

Budweiser is a famous American brand of beer, which was first founded in 1876 by Anheuser-Busch. Today, Budweiser has its business with a significant ...

Custom-Made & Branded Solutions For Refrigerators & Freezers

Nenwell has extensive experience in customizing & branding a variety of stunning and functional refrigerators & freezers for different businesses...

Post time: Jun-01-2024 Views: